DETAILS

Shipping Cutoff Times

| Shipping Type | Order By |

|---|---|

|

Standard Ground Small Parcel FREE - On orders over $25 View Transit Map |

7:00 PM CST |

|

Next Day Air (Calculated at checkout) |

3:00 PM CST |

|

Standard Ground Freight FREE - On orders over $25 |

1:00 PM CST |

- Shipping cutoff times apply to in-stock items. Please note item lead-times when placing your order.

- Orders placed on weekends or holidays will be processed the next business day.

Browse Parts By Product Model

In most cases the best way to find Greenheck replacement parts is with your product serial number. However, select Greenheck parts are only available based on your product model. Please select from the following product models to identify and purchase replacement parts.

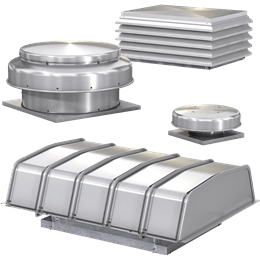

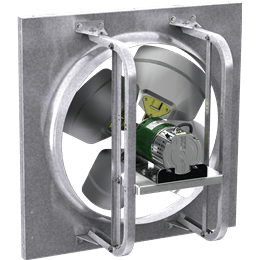

Models:

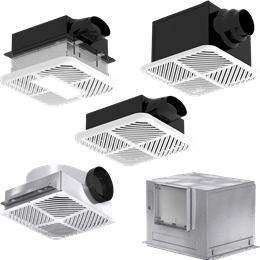

CSP, CSP-A, CSP-B, SP, SP-A, SP-AP, SP-B, SP-C, SP-L, SP-LP, SP-VG

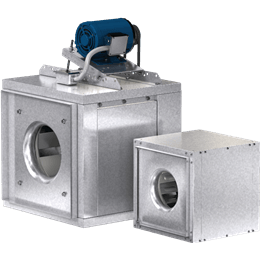

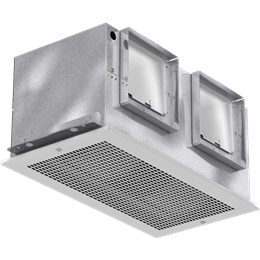

Ceiling exhaust fans are ideal for clean air applications such as bathroom and general exhaust.

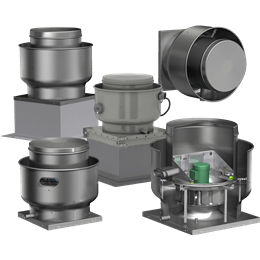

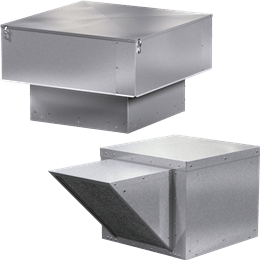

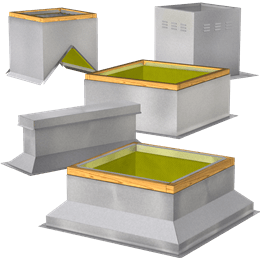

Roof support structures for fans and ventilators on flat, pitched, or ridged roofs.