| Shipping Type | Order By |

|---|---|

|

Standard Ground Small Parcel FREE - On orders over $25 View Transit Map |

7:00 PM CST |

|

Next Day Air (Calculated at checkout) |

3:00 PM CST |

|

Standard Ground Freight FREE - On orders over $25 |

1:00 PM CST |

- Shipping cutoff times apply to in-stock items. Please note item lead-times when placing your order.

- Orders placed on weekends or holidays will be processed the next business day.

Conference Room

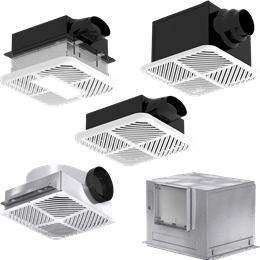

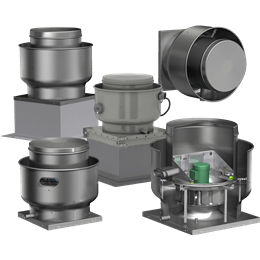

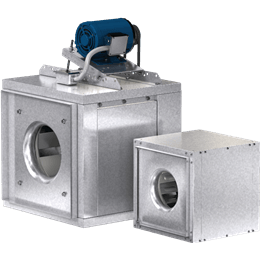

Inline Cabinet Fan (Model CSP) |

|

|

High performance fans designed for exhaust, supply or return air applications where low sound levels are required. |

Square Centrifugal Inline Fan (Model SQ, BSQ) |

|

|

Ideal selection for indoor clean air applications including exhaust, intake, return or make-up air. |

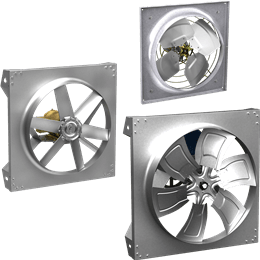

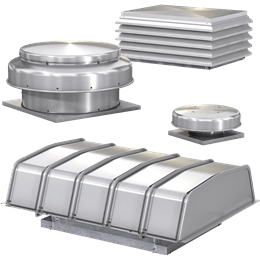

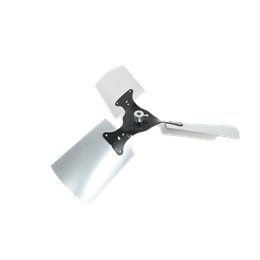

Axial Roof Exhaust Fan (Model AE)

Designed for reliability and economy in low pressure/low volume applications.

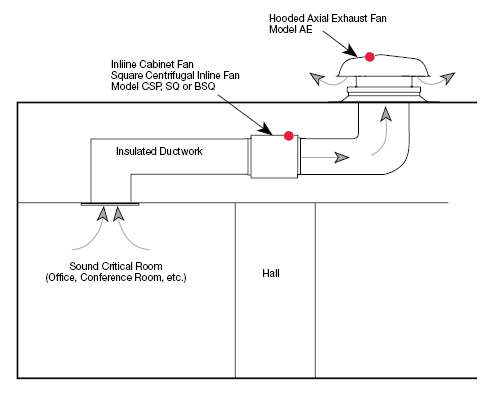

Typically, a conference room will require 4-10 air changes per hour. This is in accordance to ASHRAE Standard 62.1. In a room like this, it is also critical that the exhaust fan perform it's function without being distracting. The illustration above demonstrates that for sound critical applications, it is best to install your ventilation equipment above a less sound critical area such as a hallway or utility room using a ducted system. In addition, the use of a gravity ventilator will allow the exhaust air to pass freely through a specified area on your roof. To calculate the amount of CFM you need to exhaust from your Sound Critical Room, simply determine the volume of your room (LxWxH) and divide by the number of minutes per air change. For example:

25'L x 25'W x 15'H = 9,375 ft3

8 air changes per hour : 60 mins. / 8 = 7.5 minutes

9,375 ft3 / 7.5 minutes per air change

1,250 CFM

*NOTE - Your hooded axial exhaust fan should be sized to exhaust the same amount of air that your inline fan is exhausting..

The pressure generated by fans in ductwork is very small. Yet, accurately estimating the static pressure is critical to proper fan selection. Fan static pressure is measured in inches of water gauge. One pound per square inch is equivalent to 27.7 in. of water gauge. Static pressure in fan systems are typically less than 2 in. of water gauge, or 0.072 Psi.

The amount of static pressure that the fan must overcome depends on the air velocity in the ductwork, the number of duct turns (and other resistive elements), and the duct length. For properly designed systems with sufficient make-up air, the guidelines in the table can be used for estimating static pressure.

Static Pressure Guidelines | |

| Non-Ducted: | 0.05 inches to 0.20 inches |

|---|---|

| Ducted: | 0.2 inches to 0.4 inches per 100 feet of duct (assuming duct air velocity falls within 1,000-1,800 feet per minute) |

| Fittings: | 0.08 inches per fitting (elbow, register, grille, damper, etc.) |

| Important: Static pressure requirements are significantly affected by the amount of make-up air supplied to an area. Insufficient make-up air will increase static pressure and reduce the amount of air that will be exhausted. Remember, for each cubic foot of air exhausted, one cubic foot of air must be supplied. | |

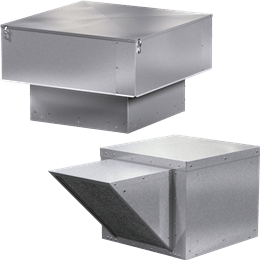

Click on a hotspot to view products that relate to the image on the diagram.

Click on a hotspot to view products that relate to the image on the diagram.