| Shipping Type | Order By |

|---|---|

|

Standard Ground Small Parcel FREE - On orders over $25 View Transit Map |

7:00 PM CST |

|

Next Day Air (Calculated at checkout) |

3:00 PM CST |

|

Standard Ground Freight FREE - On orders over $25 |

1:00 PM CST |

- Shipping cutoff times apply to in-stock items. Please note item lead-times when placing your order.

- Orders placed on weekends or holidays will be processed the next business day.

Manufacturing

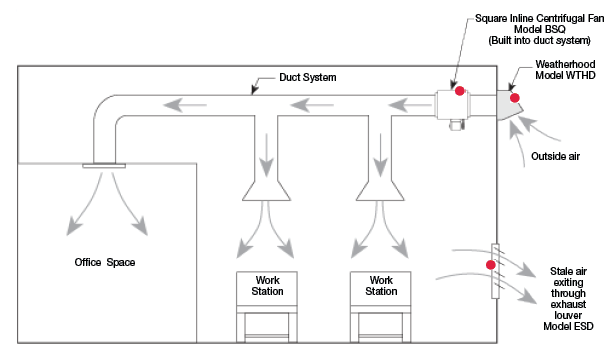

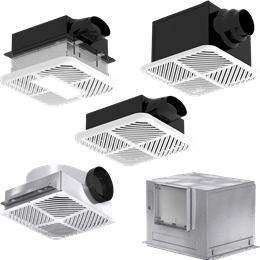

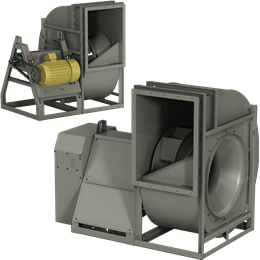

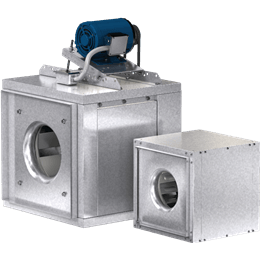

Square Centrifugal Inline Fan (Model BSQ)

Ideal selection for indoor clean air applications including exhaust, intake, return or make-up air.

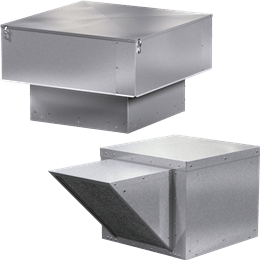

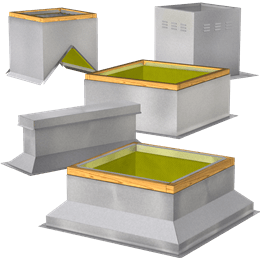

Weatherhood (Model WTHD)

Designed to shield wall openings from rain and snow.

Stationary Extruded Aluminum Louver (Model ESD-635DE)

Designed to protect air intake and exhaust openings in building exterior walls.

In industrial applications such as welding facilities or manufacturing plants, it is recommended that the air be changed every 3-5 minutes due to the processes that typically occur in these type of facilities. Good indoor air quality keeps workers comfortable and productive. In order to size a blower for your facility, you must determine the volume of your room (LxWxH) and divide it by the number of minutes per air change. For example:

30'L x 30'W x 25'H = 22,500 ft3

22,500 ft3 / 4 minutes per air change

5,625 CFM

An inline centrifugal fan like the one seen in the illustration above is used in conjunction with a system of ducts which are placed over the various work stations. The use of ductwork increases the resistance in your system and causes higher static pressures which also needs to be considered when sizing your exhaust fan.

The pressure generated by fans in ductwork is very small. Yet, accurately estimating the static pressure is critical to proper fan selection. Fan static pressure is measured in inches of water gauge. One pound per square inch is equivalent to 27.7 in. of water gauge. Static pressure in fan systems are typically less than 2 in. of water gauge, or 0.072 Psi.

The amount of static pressure that the fan must overcome depends on the air velocity in the ductwork, the number of duct turns (and other resistive elements), and the duct length. For properly designed systems with sufficient make-up air, the guidelines in the table can be used for estimating static pressure.

Static Pressure Guidelines | |

| Non-Ducted: | 0.05 inches to 0.20 inches |

|---|---|

| Ducted: | 0.2 inches to 0.4 inches per 100 feet of duct (assuming duct air velocity falls within 1,000-1,800 feet per minute) |

| Fittings: | 0.08 inches per fitting (elbow, register, grille, damper, etc.) |

| Important: Static pressure requirements are significantly affected by the amount of make-up air supplied to an area. Insufficient make-up air will increase static pressure and reduce the amount of air that will be exhausted. Remember, for each cubic foot of air exhausted, one cubic foot of air must be supplied. | |

Click on a hotspot to view products that relate to the image on the diagram.

Click on a hotspot to view products that relate to the image on the diagram.