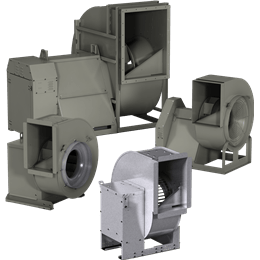

Centrifugal Blowers

OVERVIEW

USF

The USF has many construction configurations to choose from.

Galvanized Construction:

This is going to be the most economical fan available for its performance range. Constructed of heavy gauge galvanized steel, these fans are available in direct or belt drive arrangements.

Coated Steel Construction:

Coated steel material allows for the most configurations and a lower cost second to galvanized construction. This would be considered more of a standard fan offering with more options and accessories. These fans offer a corrosion-resistant coated finish and are suitable for spark resistant, restaurant grease exhaust, high temperature or general ventilation applications.

Aluminum Construction:

Aluminum fans are an excellent choice for moist or humid environments where there is concern about the fan’s exterior corroding. Aluminum is more costing than steel and doesn’t offer the same level of configurations or accessories as steel. Aluminum fans can either be mill-finish or coated.

Stainless Construction:

Stainless fans are the most expensive, but the only choice in applications requiring continuously high airstream temperatures. Stainless fans are mill finish and like aluminum and galvanized fans, have a more limited offering than coated steel fans.

The USF product has many types of wheels available in multiple grades of construction to meet the required level of performance.

- Forward-Curved (FC): Economical wheel. The forward-curved wheel has poor efficiency, but is low cost and quiet.

- Backward-Inclined (BI): Standard wheel. The backward-inclined wheel is a general-purpose type capable of performing most applications and available in multiple materials.

- Airfoil (AF): Premium wheel. The airfoil wheel offers a higher efficiency for reducing energy consumption.

The USF is designed to handle small to large volumes of air at low-to-high pressures in commercial and some industrial applications. These fans fit a broad range of fan applications such as hazardous environments, emergency smoke control, spark resistance, high volume/pressure capabilities, etc. Alternate construction materials are also available for corrosive or extreme high-temperature applications. Split housing also available for limited access installations.

- Arrangements 1, 4, 8, 10

- Up to 160,000 cfm

- Up to 21 in. wg

- Spark A, B or C resistant construction available

- Alternate material construction: Aluminum and Stainless steel

UL/cUL Listed for Electrical (UL/cUL-705), Grease Exhaust (UL/cUL-762) and Power Ventilators for Smoke Control

AMCA licensed for FEI, Air & Sound Performance

- Catalogs

- Instruction Manuals

- Specifications

-

Drawings

-

STATIC MODEL DOWNLOAD3D CAD2D CAD

-

USF

USF

-

- Application Information

- Videos

- Other Product Information

- Warranty

- Project Profiles