Project Profile: Yuma High School

The Challenge

• Prevent serious mold issues from reoccurring

• Design a system to handle seasonal humidity changes

• Meet current outdoor air standards

Yuma High School is one of the oldest schools in Arizona. Its 3,000 students occupy two buildings that have undergone multiple renovations and additions. Old Main, built in 1910 is a three-story, 30,000 square foot facility, and Snider Hall, built in 1921, is two stories with 20,000 square feet of space.

One might not typically expect mold problems to occur in the arid Arizona climate, but from mid-July through September, Yuma experiences "monsoon season." Over the years, serious mold issues developed in both Yuma school buildings. Two-pipe fan coil units installed in each classroom were not sized to handle the increased humidity. In addition, the schools were designed to provide only 5 cfm of outdoor air per person. Even less was being provided because outdoor air dampers were often closed. The lack of ventilation resulted in CO2 levels ranging from 2000 to 6000 ppm.

In 2000, the school district spent millions of dollars cleaning up the mold, but didn't really address the cause of the problem until 2003 when the district decided to invest in a more reliable, economical HVAC system. The new system was designed to not only keep the mold problems from reoccurring, but also to comply with the 15 cfm /person outdoor air requirement of ASHRAE Standard 62.

Greenheck’s Solution

• Economical, dedicated outdoor air system (DOAS) with energy recovery

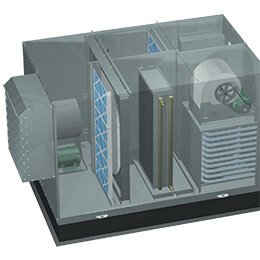

John Sternitzke of Sternco Engineers had used energy recovery products in the past to handle the excessive humidity of the monsoon season, as well as for preconditioning the outdoor air year-round to individual rooftop units. On this job, he determined that employing a dedicated outdoor air system (DOAS) with energy recovery would be the most economical solution. The ventilation solution for Yuma High School utilizes Greenheck Model ERCH, which combines the benefits of a total enthalpy wheel with supplemental cooling and heating. A total of seven ERCH units with chilled water cooling and hot water heating were installed. One ERCH per floor supplies the ventilation air at 65 degrees, 35% rh to the return side of the fan coil units in each classroom. The exhaust air is pulled from the corridors and routed back to the ERCH. This system concept addressed two very important concerns - 1) the ERCH units eliminated the need for the fan coil units to handle the latent load of the outdoor air and 2) because the ERCH handles the entire outdoor air load, the outdoor air volume was able to be increased to meet current ventilation standards without additional cooling equipment.

The Results

• Improved indoor air quality and humidity, reduced CO2 levels, accomplished within budget.

The incorporation of the dedicated outdoor air concept at the Yuma School district has proven to be a tremendous success. More than a year after installation of the Greenheck units, tests for mold were negative. "Our indoor air quality has improved, especially the humidity," says Dave Folsom, Director of Maintenance for the Yuma School District. Dave goes on to say that "CO2 levels have been reduced to 1200 ppm or less" and "math and science scores have jumped."

John Sternitzke also expressed his satisfaction with the equipment describing them as "industrial strength." By selecting Greenheck's Model ERCH, Sternitzke was able to specify a semi-custom energy recovery unit that satisfied the needs of the school district while staying within their budget. In addition, he knows the school district now has a top performing ventilation system. The energy wheel is certified per ARI Standard 1060 for Air to Air Energy Recovery Devices and the entire unit is AMCA Licensed for Air Performance.