Energy Recovery for Battery Room Ventilation

Data centers are popping up all over as the need for data storage increases at an exponential rate. These centers have battery rooms, which store banks of batteries to provide power in case of an outage. Battery rooms require proper ventilation, particularly due to the unique challenges posed by the hydrogen gas that is produced by the sulfuric acid inside the batteries.

Energy recovery ventilators (ERVs) using an enthalpy core have proven effective for ventilating battery rooms. Before deciding on a solution, consider the relevant standards and local codes.

Battery Room Ventilation Requirements

While charging, batteries used in data centers emit hydrogen gas. This gas, which is lighter than oxygen, rises to the highest point within the room. It cannot be detected by sight or smell, and when it reaches a concentration of only 4% by volume, the air in the room becomes flammable and potentially explosive.

As a result, several HVAC industry standards and fire codes govern spaces where hazardous gases such as hydrogen gas might accumulate. The National Fire Protection Association (NFPA) requires mechanical ventilation that either limits the maximum concentration of flammable gas to 25% of the lower flammable limit (LFL) of the total volume of the room during a worst-case scenario when all batteries are charging, or ventilates at a rate of 1 cubic foot per minute (cfm) of the room’s floor area.

ASHRAE standard 62.1 has essentially the same two requirements: continuously ventilate the space at 1 cfm, or limit hydrogen gas concentration to 25% of the LFL. Since the LFL is 4%, this is a low 1% concentration.

Using Energy Recovery to Meet Requirements

Multiple solutions to these requirements are possible. Many data centers have an exhaust fan expelling the hydrogen-tainted air and a supply fan putting in either outdoor or transfer air. Heating and cooling components would likely then be needed to temper the air. This adds to the energy costs of a data center that already has long racks of servers which consume electricity and must be temperature-controlled to avoid overheating.

An alternative to minimize energy consumption, as well as exhaust hydrogen buildup and introduce fresh outdoor air into the battery space, is an ERV with enthalpy core. An ERV recovers energy from the exhaust air to pretreat outdoor supply air. Enthalpy is the combination of sensible energy (temperature that can be felt and measured) and latent energy (heat energy contained within the air’s moisture).

The media within the ERV is made of corrugated and layered fiber or polymer and has no moving parts. The energy transfer occurs through the material as the supply and exhaust airstreams travel through the corrugated pathways. Enthalpy cores can recover 50–65% of energy from exhaust air and have a cross-leakage of less than 1%.

|

| Enthalpy Core |

This technology has numerous advantages in a battery room environment. It continually exhausts the hydrogen gas to prevent buildup in the room, keeping the hydrogen concentration below 1%. It also continually introduces fresh outdoor air, ventilating at more than 150 cfm. It also reduces the building’s large cooling load through enthalpy recovery of the energy in the exhausted air.

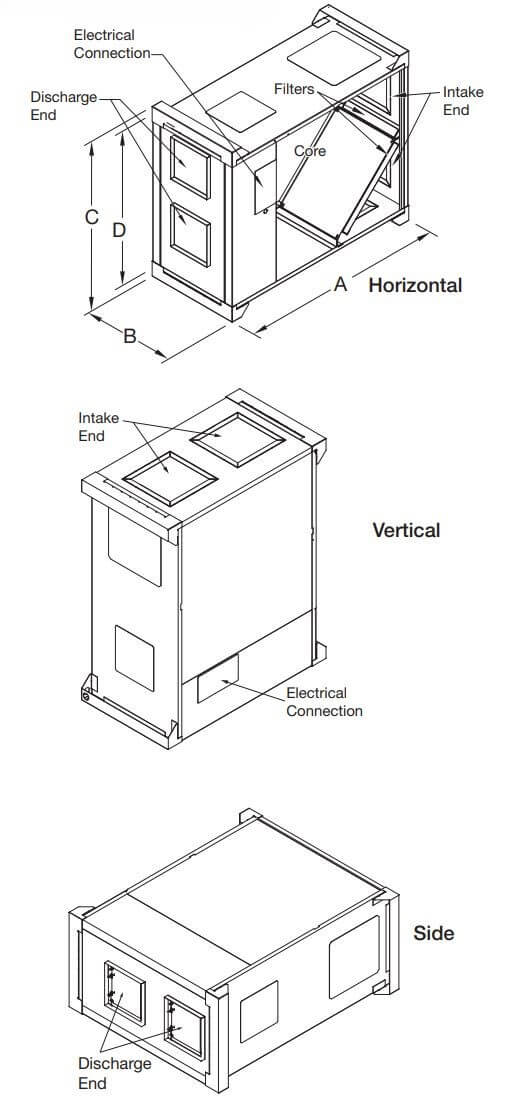

Small ERVs such as Greenheck’s MiniCore can fit inside a snug battery room and be mounted anywhere on the walls or ceiling, in any configuration. See the below illustrations for horizontal, vertical, and side installation options. Integrated airflow monitoring provides continuous feedback on how the unit is functioning.

|

| ERV Installation Options |

Additional Ventilation Safety Precautions

Battery rooms should have adequate ventilation to remove gases released during charging. If ventilation openings penetrate a rated barrier, fire or fire/smoke dampers may be required by code. Consult the local code and authority having jurisdiction (AHJ) for requirements. Fire or fire/smoke dampers can be installed in ductwork openings through floors or walls to protect the opening during a fire event. Heat sensing devices on the damper detect when elevated temperatures reach a set threshold, and upon activation command the damper to close. Dampers are effective means to interrupt and prevent the spread of fire and smoke from the point of origin.

Finally, a hydrogen gas detector should be integrated with the HVAC system in a battery room. It will alarm and activate if hydrogen levels reach a set threshold, initiating a higher amount of ventilation.

Conclusion

While numerous HVAC solutions for ventilating a data center battery room are possible, an ERV with enthalpy core is a space-efficient technology that provides continuous ventilation and energy recapture to reduce the building’s cooling load. The MiniCore also features direct drive fans and Vari-Green® electronically commutated motors.

MiniCores can be selected through Greenheck’s online application suite for engineers, eCAPS®, which can be linked directly to Autodesk Revit® using Greenheck’s Bridge for Revit® add-in.

Finally, ERVs in battery rooms can be combined with other fire protections such as a hydrogen gas detector and fire dampers in ductwork. Greenheck’s line of fire dampers is UL 555 classified in the categories of both dynamic rated, where HVAC systems remain operational during a fire emergency, and static rated, where HVAC systems shut down automatically in the event of a fire.

Dampers Data Centers Energy Recovery

from