Protecting Ventilation Openings for Storm Shelters and Tornado Safe Rooms; FEMA Louver Requirements

Springtime in many parts of North America ushers in many changes. Snow melts, temperatures rise and the land starts producing again. These are welcome changes for many, but these changes do not come without some challenges. Spring is a volatile season and is often known for violent weather. Tornadoes and strong storms cause damage to property, injury and even loss of life.

These weather events are not preventable. However, design and construction guidelines exist to reduce the effects of these storms, particularly for storm shelters.

The design and construction of shelters for use during significant high wind weather events must follow standards and guidelines set by the United States government and third-party associations. This includes products used in the construction of the shelter. The two main entities involved are the Federal Emergency Management Administration (FEMA) and the International Code Council (ICC).

FEMA provides guidelines for both community and residential safe rooms. FEMA Publication P-361, “Safe Rooms for Tornadoes and Hurricanes: Guidance for Community and Residential Safe Rooms,” provides important information about the design and construction of these safe rooms. FEMA P-361 (Figure 1) includes best practices for the design, construction, and operation of community and residential safe rooms. These best practices also include consideration for ventilation requirements, emergency management and risk assessment information.

|

| Figure 1 - These two publications provide direction for the design and construction of safe rooms and storm shelters including ventilation |

ICC 500, “Standard for the Design and Construction of Storm Shelters,” is another essential publication for storm shelter design and construction. This document systematically arranges FEMA P-361 and provides the building codes and standards for the storm shelter design and construction. The scope of the ICC 500 publication is narrower than the FEMA P-361 and focuses specifically on the design, construction and installation requirements of storm shelters. Any safe rooms constructed using FEMA funds must comply with the requirements of ICC 500 and FEMA P-361.

An important aspect of the storm shelter design is the protection of openings including the ventilation openings against extreme wind and wind-borne debris while still providing adequate airflow to the shelter occupants. Wind speeds of up to 250 mph must be considered when designing these storm shelters for tornado regions. Proper product selection and application is critical to maintaining building envelope ratings.

One of the main design criteria relative to the building envelope is missile impact resistance. Missile impact criteria for impact-protective systems, including louvers, are identified in ICC 500 chapter 8. The missile used in testing is a No. 2 or better grade soft lumber 2 x 4, weighing 15 pounds with a length of 13.5 feet. For a safe room designed to withstand a 250-mph wind speed, the missile speed will be 100 mph for vertical surfaces and 67 mph for horizontal surfaces.

Chapter 8 of the ICC 500 publication also includes pressure-testing procedures for impact protective systems to include both positive and negative cyclic design pressures. This procedure subjects the test specimen to very high positive and very high negative wind loads while designed to ensure that the impact-protective system can withstand the wind-induced pressure experienced during a significant weather event.

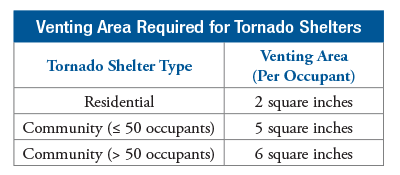

The ICC 500 publication also clearly identifies ventilation requirements, and these vary based on the storm shelter application and occupancy. Residential shelters (maximum occupancy is 16 people) require two square inches of venting area per occupant. Community shelters with occupancy of 50 or less; require 5 square inches of venting area per occupant. Occupancy of 50 or greater require 6 square inches of ventilation per occupant. (Table 1) This section also provides specific information for the proper location and placement of natural ventilation openings within the structure. The location of the ventilation openings is critical to provide adequate cross ventilation in the shelter.

|

| Table 1 |

Section 108.2 of the publication addresses labeling. This section explains the requirements for the labeling of impact protective systems, including louvers, to show compliance with the ICC 500 standard. An approved agency, such as Underwriters Laboratory (UL), labels these products when required by the applicable code or jurisdiction.

A louver selection that meets FEMA requirements to protect ventilation openings in the structure’s envelope is common. When using louvers in FEMA shelter applications, it is important to verify the selected louvers have the ICC 500 impact qualification, meet the cyclic wind load and high wind load ratings, and have a third-party verification listing. The Underwriters Laboratory (UL) is one example of a third-party verifier. The manufacturer may also choose to test the louver to Air Movement and Control Association, International, Inc. (AMCA) standard 500-L for Air and Water performance. This testing validates the manufacturer’s published performance information for the louver regarding air and water penetration performance and allows the louver to be applied with confidence that it will perform as specified.

With a wide variety of installation and configuration options available, these louvers can be configured for nearly every safe room and storm shelter application. This installation flexibility, combined with the stringent testing qualifications and third-party listing, makes the FEMA compliant louvers the ideal choice for FEMA-funded projects.

Learn more about louver products that meet FEMA requirements for protection from tornadoes.

Louvers Violent Weather

from