Redundant Lab Exhaust Systems: Are You Selecting the Best Option for Safety?

Safety. Reliability. Ensure proper design and installation of systems to keep a laboratory open and operational. Laboratories must meet these requirements. However, labs have stringent ventilation needs when compared with other applications.

Many labs work on critical research with potential for infection or contamination of laboratory researchers. Laboratory exhaust fan systems provide the necessary ventilation containment for safety and reliability, keeping the laboratory facility in operation. Because of this, most laboratories use redundant fan exhaust systems to protect lab occupants and maintain integrity of research projects.

Redundancy in a multiple laboratory exhaust fan system refers to the ability to maintain containment and proper ventilation in certain situations. N is typically used to designate the number of fans used per fan system during Normal (N), and most common, operation. This could be 1, 2, 3, … etc. as the actual number of fans is tailored to each project application and situation. On multiple fan systems the redundancy question refers to how the system will be controlled in a situation where a fan is not operable. The choice of redundancy will impact not only the operation of the lab and the availability, sizing and performance of the fan selections.

There are three choices for redundancy selecting lab fans and determining their operation: None (no redundancy), N + 1, and N-1.

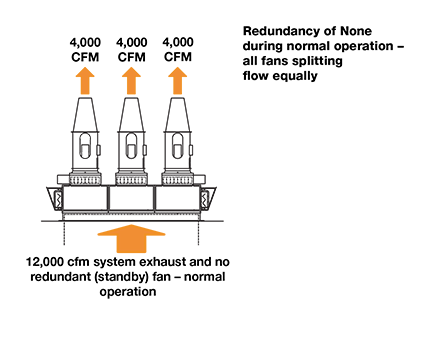

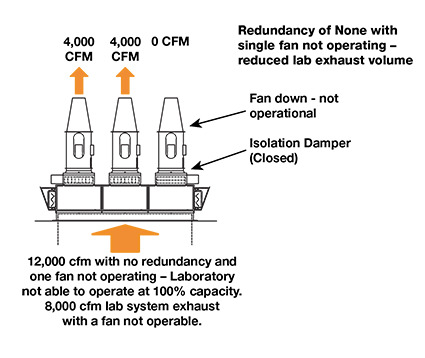

None – No Redundancy

The system design for a redundancy of None has a total airflow equally divided between the number of fans selected (Figure 1) with no provision to supplement airflow if a fan is not working. Such a system would operate with reduced system airflow in that situation (Figure 2). The benefit of this system is having a lower first cost because the fans are not oversized to compensate for the decreased airflow, nor are there extra fans to substitute if one fan becomes inoperable.

Example:

Total quantity of fans: 3

Redundancy type: None

Total exhaust flow: 12,000 cfm

Flow through each normally operating fan: 4,000 cfm

|

| Figure 1 – Redundancy of None during normal operation - all fans splitting flow equally |

|

| Figure 2 – Redundancy of None with single fan not operation – reduced lab exhaust volume |

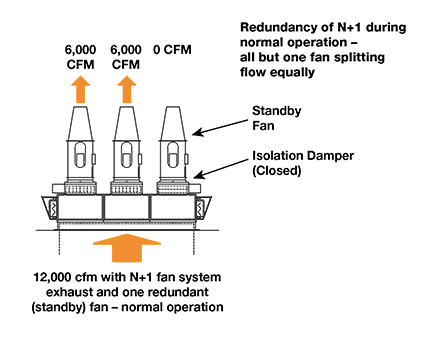

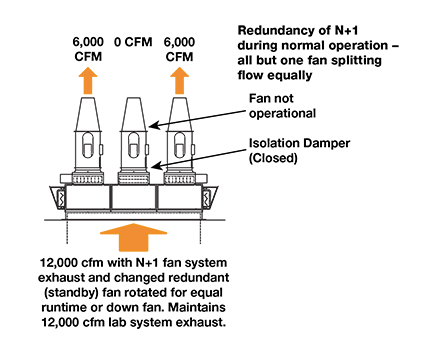

N+1 – Fan on Standby

N+1 is also referred to as having a fan on standby. The design of the exhaust system has one completely redundant fan (Figure 3). All fans in this system never operate at the same time. The redundant (standby) fan in the exhaust system is a fan that sits idle until needed (Figure 4). It is available in the event of maintenance to the other existing fans to prevent system downtime.

Individual fan airflow is calculated by taking the system total airflow and dividing by the number of fans minus the one on standby (in case another fan becomes inoperable). It is a preferred practice when controlling this system to keep equal run time on all fans. Therefore, the standby fan is not always the same. It is common to rotate the standby fan each week, so all fans receive consistent run time. This configuration provides 100% backup and allows the laboratory to remain fully operational.

Example:

Total quantity of fans: 3

Redundancy type: N+1

Total exhaust flow: 12,000 cfm

Flow through each normally operating fan: 6,000 cfm

|

| Figure 3 – Redundancy of N+1 during normal operation - all but one fan splitting flow |

|

| Figure 4 – Redundancy of N+1 with single fan down - all but one fan splitting flow equally |

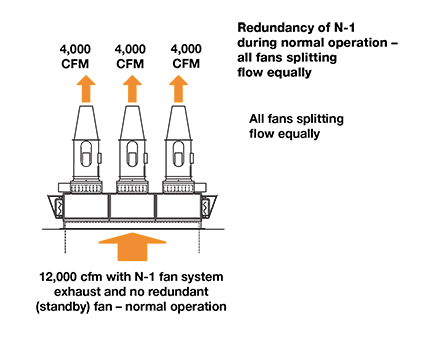

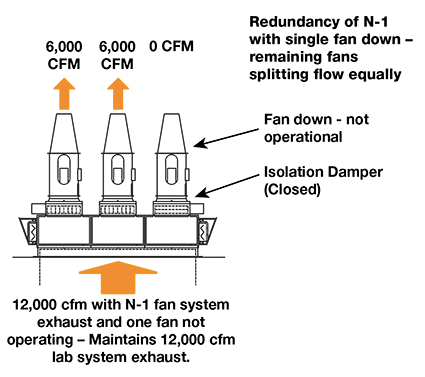

N-1 – Equal Airflow but Sized to Compensate

The design of an N-1 system has all the fans operating at the same time and divides the airflow equally between each (Figure 5). However, fans are sized with the capacity to compensate for the loss of a fan and operate at 100% airflow with the remaining fans (Figure 6). This solution is quieter and more efficient during normal operation because of reduced running speed and a lower nozzle discharge velocity. A secondary advantage is that operational run time is equal for all the fans reducing the complexity of controls systems that maintain equal runtime between all fans. The N-1 redundancy option provides 100% backup and allows the laboratory to maintain operations.

Example:

Total quantity of fans: 3

Redundancy type: N-1

Total exhaust flow: 12,000 cfm

Flow through each normally operating fan: 4,000 cfm

|

| Figure 5 – Redundancy of N-1 during normal operation - all fans splitting flow equally |

|

| Figure 6 – Redundancy of N-1 with single fan down – remaining fans splitting flow equally |

Selecting the required redundancy for a laboratory exhaust fan system depends on the laboratory type, preferences of the facility owner/operator and their level of risk avoidance. Each exhaust system design has advantages and disadvantages as illustrated in the examples. Additional considerations for control and operation of multiple exhaust fans in laboratories should include staging fans (on/off) based on exhaust demand and controlling fan flow as an energy reduction strategy.

Which laboratory exhaust fan system is best for your application? Find out here.Laboratory Exhaust

from