Why Your Restaurant’s Neighbors Will Thank You for Using a Pollution Control Unit

As delicious as the aromas of food cooked in a commercial kitchen may be when the food gets to your table, the smoke and grease particles that cooking gives off are less enticing. That’s why many cities and counties now require kitchens that exhaust air at the ground level to use pollution control units (PCUs), which remove grease, smoke, and odor from kitchen exhaust.

Why Use a Pollution Control Unit?

Multi-use buildings (with residents living in apartments or condos above businesses such as restaurants) are becoming more common. So is awareness of the importance of clean air. PCUs filter out smoke and grease particles and have carbon-based odor control modules to take care of the remaining odor. Codes and regulations requiring them are regularly being added. However, many commercial kitchens now incorporate PCUs into their ventilation systems even if their local code does not require it, as considerate neighbors helping to keep the air clean in their communities.

Pollution Control Units with Mechanical Filters

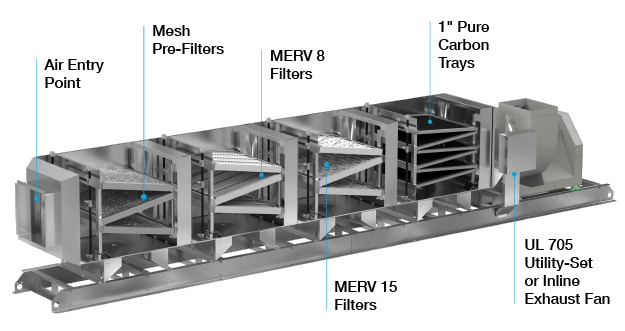

There are two main types of pollution control units. The first uses a mechanical filter (Figure 1).

|

| Figure 1 |

Even home kitchen range hoods have mechanical filters. However, at the commercial level these are much larger and more advanced. The most effective PCUs with mechanical filters use a three-stage arrangement to trap smoke and grease particles from the exhaust air. Each filter stage has its own independent pressure switches to signal when that filter needs to be replaced.

As an added courtesy to neighbors, PCUs include activated carbon trays that remove odor molecules from the exhaust air before discharging it (Figure 1).

ESP Pollution Control Units

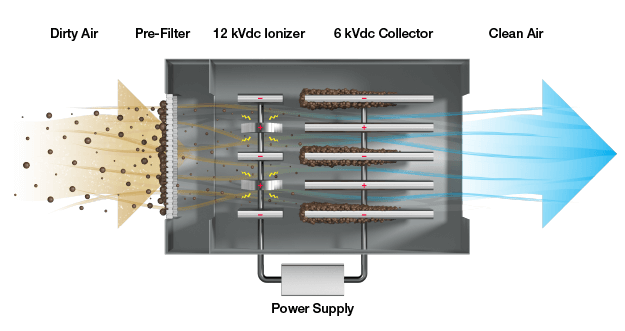

ESP provides a higher-tech alternative to filters. It stands for “electrostatic precipitator,” and it uses an electric charge to remove particles from an airstream (Figure 2).

|

| Figure 2 |

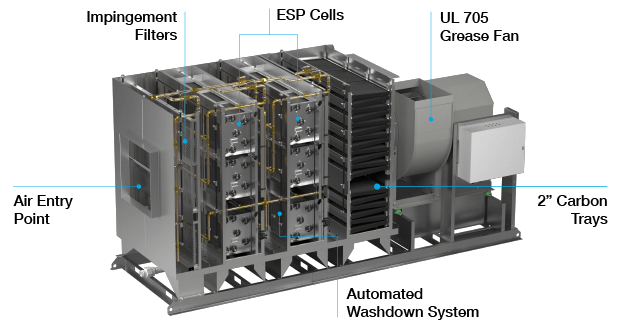

Air entering the ESP goes through an ionizer that positively charges its particles. The particles then enter a collector full of negatively charged plates, and because they are positively charged, they stick to the plates. Finally, the air passes through a column of two-inch carbon trays that take out its odor (Figure 3). The clean, odor-free air is then exhausted from the building.

|

| Figure 3 |

ESP units are self-cleaning and include a nightly scheduled wash system containing multiple spray manifolds that wash the interior of the unit.

Choosing a Pollution Control Unit

This table compares the two main PCU options.

| PCU with Mechanical Filter | PCU with ESP Technology | |

| Initial Cost | Lower | Higher |

| Maintenance | Replaces filters when the light indicates replacement is needed | Nightly self-cleaning feature. Monthly inspection recommended |

| Exhaust Capacity | 3,000–12,000 CFM | 1,500–13,500 CFM |

| Customization | Complete Ansul UL 300 fire suppression system including installation | Variable frequency drive (VFD) for system balancing or variable volume operation |

| Activated Carbon Trays | Yes | Yes |

| Listed to Code UL 8782 | Yes | Yes |

A PCU with ESP technology will have a higher initial cost, but its maintenance and replacement costs will be lower than the mechanical filter alternative.

Learn More

Find a Greenheck Representative: Find a representative in your area who can tailor a pollution control recommendation to the needs of your project.

Kitchen Pollution Control Units: Check out Greenheck’s Grease Trapper™ and Grease Trapper ESP™ products to eliminate kitchen pollution particles and odors.

from