Ceiling radiation dampers (CRDs) are critical fire and life safety devices commonly required by building codes. When installing them, you must adhere to the manufacturer’s instructions, rated assembly requirements, and product listing. In this post, Greenheck answers frequently asked questions about applying, specifying, and installing CRDs.

What is a ceiling radiation damper?

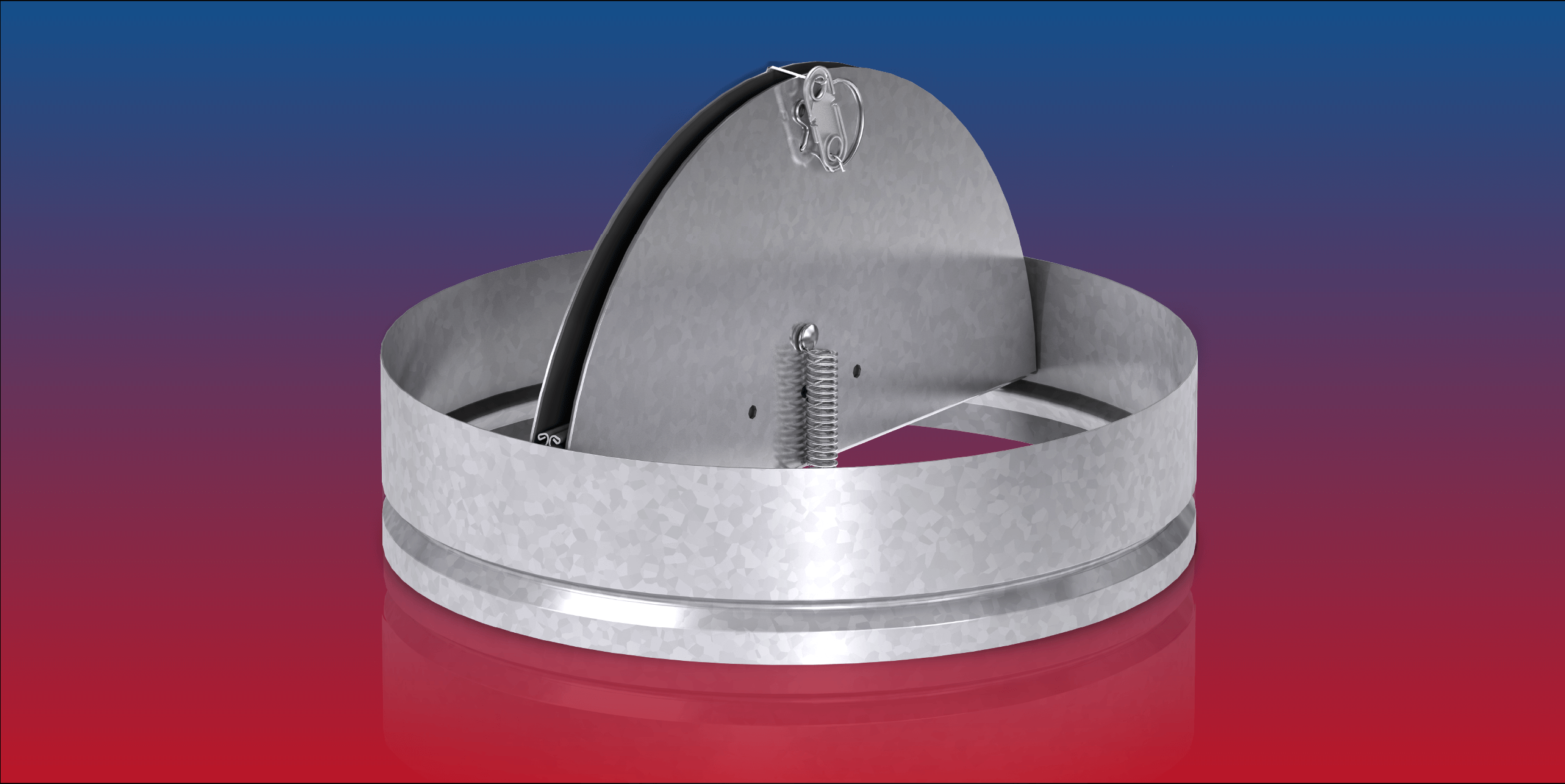

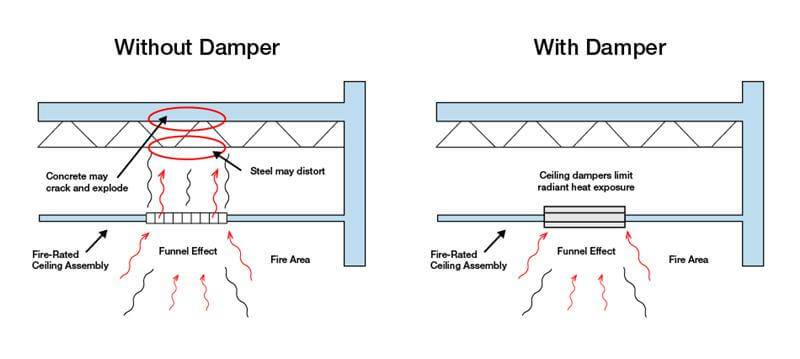

Ceiling radiation dampers help maintain a building’s fire resistance and protect spaces above the ceiling during a fire event. Unlike a fire damper, which limits the spread of flame, a CRD limits the transfer of radiant heat through an air outlet or inlet opening in the ceiling. It is often installed behind a diffuser, grille, or exhaust fan. Figure 1 shows a side-by-side comparison of the effects radiant heat can have above the ceiling during a fire when a CRD is not used to protect an opening, versus when a CRD is installed.

|

| Figure 1 |

Which standards govern ceiling radiation dampers?

The most relevant standards are the International Building Code (IBC) and Underwriters Laboratories (UL).

- IBC Chapter 7: “Fire and Smoke Protection Features, Section 717.3.1 Damper Testing” lists the applicable test standards for each life safety damper type. Ceiling radiation dampers shall comply with the requirements of UL 555C Standard for Safety, Ceiling Dampers or shall be tested as part of a fire-resistance-rated floor- or roof-ceiling assembly in accordance with UL 263, Standard for Fire Tests of Building Construction and Materials.

- UL 555C governs the requirements and methods of tests that apply to ceiling dampers and ceiling air diffusers intended for installation in floor- or roof-ceiling assemblies that have at least a 1-hour fire resistance rating.

What applications are ceiling radiation dampers used in?

UL 555C-listed ceiling radiation dampers are approved for installation in assemblies that specify the use of hinged-door-type dampers. We commonly see these dampers in air inlet/outlet membrane penetrations located in fire-rated, lay-in acoustical tile ceilings in a non-combustible (steel) truss system fire-resistance-rated for 3 hours or less.

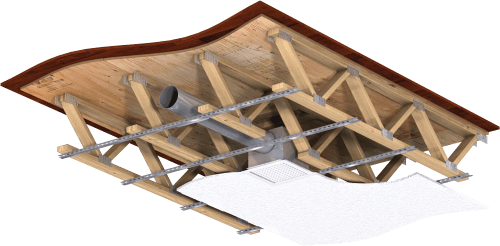

A UL 555C-listed ceiling radiation damper may also be tested in accordance with UL 263 and listed for use in a specific floor- or roof-ceiling fire-resistance-rated assembly. UL 263-listed dampers are often used in applications such as low-rise multifamily apartments, hotels and motels, assisted living facilities, dormitories, and residence halls, in gypsum board ceilings in combustible (wood) truss or joist systems fire-resistance-rated for 1 hour. See Figure 2.

|

| Figure 2: Ceiling radiation damper in a combustible wood truss floor-ceiling assembly. |

If a damper is listed for use in a design, can I use it in a different design?

Ceiling radiation dampers that have been evaluated and listed for use in a specific combustible wood truss or joist system are only intended for use in that design. The listing agency may require additional testing and/or engineering evaluations to qualify the damper for use in other floor- or roof-ceiling assemblies. The damper manufacturer’s installation instructions should list all the applicable floor- or roof-ceiling designs that a specific model damper has been approved for, as the instructions incorporate the listings.

What about substituting a UL 555C damper for a UL 263 damper?

While it may be true that the damper that was tested in accordance with UL 263 in a specific floor or roof/ceiling assembly is also a UL 555C-classified damper, you cannot substitute a UL 555C damper for the listed damper in a specific UL 263 floor- or roof-ceiling assembly unless that damper has been evaluated for use in that specific assembly.

The damper listed in a UL 263 assembly is just a part of the complete rated assembly, which includes the damper, duct, trusses, gypsum board, insulation, and all other construction components. The fire-resistance ratings apply to entire tested assemblies, as opposed to assemblies’ individual components and materials. As such, ceiling dampers themselves are not fire-resistance-rated. Instead, the ratings ceiling dampers carry indicate the dampers’ suitability for use in specific rated floor-ceiling and roof-ceiling assemblies as a system.

Architectural specifications that reference a specific UL floor- or roof-ceiling assembly often reference dampers listed by either the Gypsum Association’s Fire Resistance Design Manual or Warnock Hersey (ETL).

The Gypsum Association is not a testing agency. Its listings are based on test data from various accredited third-party laboratories, all of which conduct fire tests of floor-ceiling and roof-ceiling assemblies in accordance with UL 263. The ceiling-damper models approved for use in a specific Gypsum Association design can be determined by consulting the test reports and/or design numbers of the testing agency listed in the design manual.

Warnock Hersey-listed dampers are tested by Intertek (ETL) in accordance with applicable UL standards as required by the IBC. As such, Intertek maintains a product directory that details the damper manufacturer, applicable test standards, and applicable UL floor- or roof-ceiling assembly approvals.

It is important to note IBC does not have a specific listing agency requirement for life safety dampers. Chapter 7, Section 717.3.1 states that dampers shall be “listed and labeled in accordance with” the applicable referenced UL standard. It is at the discretion of the Authority Having Jurisdiction (AHJ) to accept and approve damper installations as well as the approval agencies that test and list the product.

These requirements are outlined in the manufacturer’s approved installation instructions for that specific damper model and are not typically found in the listing agency’s floor- or roof-ceiling assembly listing. However, the assembly listing will detail other critical damper-related design and installation requirements. Failure to adhere to these details and instructions could result in the improper operation of the damper and void the fire resistance rating of the assembly.

When specifying and installing CRDs that have been evaluated for use in 1-hour fire-resistance-rated combustible wood truss (or joist) floor- or roof-ceiling assemblies, consider the following:

- In most applications, ceiling radiation dampers require a steel or fiberglass plenum (also referred to in the industry as a “boot” or a “box”). These plenums have specific construction requirements that can either be factory-provided, or if approved by the listing agency, field-fabricated. Damper manufacturers will outline field-provided plenum construction requirements. Some manufacturers may also require the field installation of insulation over their factory-provided plenums, which is needed to maintain the listing of the product.

|

| Figure 3: Steel plenum for housing a ceiling radiation damper. |

- Most floor- or roof-ceiling assemblies are static-rated, meaning they are designed for HVAC systems that shut down during a fire, rather than dynamic-rated for systems that remain operational. For most static-rated assemblies, the type of approved air duct is any UL Class 0 or Class 1 flexible air duct installed according to damper manufacturer instructions. Reference specific ceiling assembly details for duct requirements.

- For ceiling design and coordination between trades, it is important to note that aggregate damper openings are specified in the assembly listing, often expressed as “shall not exceed xxx sq. in. per 100 sq. ft. of ceiling area.” This limitation will have an influence on membrane penetration placement within the ceiling.

- If possible, balancing dampers should be located at branch ducts. If balancing is required at the face of the air outlet, we recommend adding an optional volume control mechanism built into the ceiling radiation damper. There are limitations on how high damper blades can close above the ceiling, ranging from <1” to 3+” above the gypsum panel depending on manufacturer and model. The total depth of a grille with an opposed blade damper may be too deep to conform to the manufacturers’ approved installation instructions once installed inside the required plenum. Consult with your damper manufacturer for plenum restrictions when using grilles with opposed blade dampers.

Please get in touch with your local Greenheck representative if you are still unsure whether CRDs are needed for your application or jurisdiction, or if you have any questions about them. Greenheck offers ceiling radiation dampers in various sizes to protect against radiant heat in case of a fire.

from