Rooftop Units Work in Tandem with Energy Recovery

Rooftop units are a common solution for heating and cooling a building while also providing dehumidification and ventilation. They have recently undergone an upgrade in the industry with the introduction of performance RTUs, which have many modulating components that make them more responsive to the needs of building occupants. Performance RTUs can be identified by features such as an inverter scroll compressor that adjusts speed for part load conditions and an electronically commutated motor in the condensing fan that modulates to control head pressure. Our blog post “The Next Phase of Rooftop Units” has more information about what sets performance RTUs apart from basic unitary RTUs.

As efficient as performance RTUs are, a design using an RTU can be made even more efficient by adding energy recovery, and some projects may require it. Energy recovery is the recapture of energy from exhaust air to pretreat incoming air and save operating costs. It can be accomplished through an energy recovery ventilator (ERV) or through energy recovery components added to a dedicated outdoor air system (DOAS), a packaged unit that specializes in ventilation and dehumidification. Read on to learn when energy recovery is most needed, info about pairing an RTU with an ERV, and considerations for adding a DOAS unit to the rooftop as well.

How do ERVs work?

The two types of energy in the exhaust airstream are sensible energy (air temperature) and latent energy (air moisture). Unlike a heat recovery ventilator, which only transfers sensible energy, an ERV typically transfers both. It does so via either a stationary total energy core, which transfers with up to 65% effectiveness, or a total energy wheel, which rotates and can transfer with up to 80% effectiveness when the supply and exhaust airflows are balanced. Both ERVs and DOAS units can use either wheels or cores. To learn more about the energy recovery process, read our post “Moisture Transfer in Energy Recovery Ventilators.”

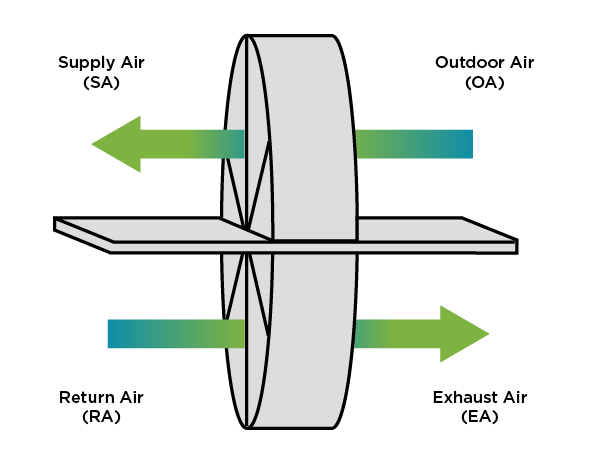

|

| A total energy wheel transfers energy from return air to pretreat outdoor air. |

When is energy recovery required?

The most common scenario for using energy recovery is when it is required by local codes and standards. The ASHRAE 90.1 standard and the International Energy Conservation Code (IECC), which are adopted at different rates by states and municipalities, require energy recovery in most U.S. climate zones under the following criteria:

- Supply airflow exceeds 5,000 cfm.

- At least 70% outdoor air is being used.

- Specific types of buildings where it would be detrimental to recapture exhaust air, such as laboratories, are excepted.

Performance RTUs ventilate at less than 70% outdoor air, so a system ventilating with only an RTU would be outside these requirements. However, in hot and humid as well as cold climates, energy recovery is often locally required or just strongly recommended. It reduces:

- The air conditioning and dehumidification loads in hot and humid climates

- The heating load in cold climates

- The operating costs in any application providing a significant percentage of outdoor air

A building owner may also wish to seek utility rebates or other local energy efficiency incentives, which energy recovery makes buildings eligible for in many cases.

How can an RTU and ERV be combined?

Combining an ERV with one or more RTUs reduces energy demand on the RTUs because the ERV brings in 100% outdoor air for ventilation, using the energy from exhaust air to pretreat incoming air for temperature and humidity. This lowers the RTU’s tempering and dehumidification loads and has the added benefit of improving indoor air quality (IAQ).

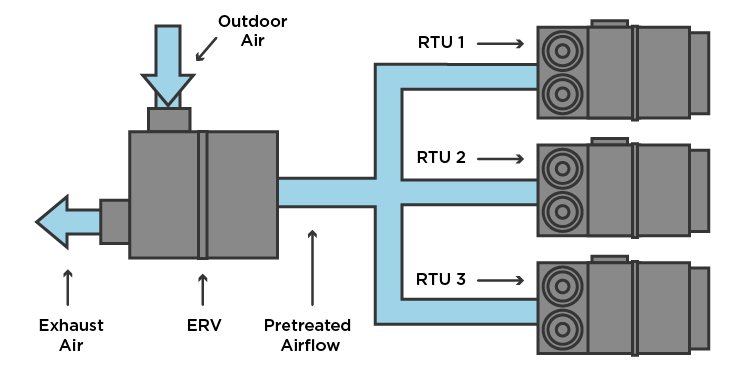

A recommended configuration for scaling up air supply is to combine an ERV with multiple RTUs. Let’s look at an office building in Wisconsin in July (summer application) as an example.

|

- The ERV pulls in hot, humid outdoor air, which it cools and dehumidifies using energy transferred from the return airstream. While the return air leaves as exhaust air, the pretreated air flows through ductwork to multiple RTUs.

- The RTUs cool the air further before supplying the air into offices. The supply air is also recirculated with return air. The cooling load for all three RTUs is reduced by about 50% because of the work done by the ERV.

Both an ERV and RTU can have factory-installed microprocessor controllers for common controls sequences that integrate with the building management system (BMS).

Recovering Energy with Dedicated Outdoor Air Systems

DOAS units with energy recovery can provide conditioned 100% outdoor air, so if space allows, they can be an efficient alternative to combining an ERV with one or more RTUs. The energy recovery technology options housed within a DOAS unit are the same as those offered by an ERV: a low-maintenance total energy core or a rotating total energy wheel that is more compact and transfers a higher percentage of energy.

In the example given above, a DOAS could be used to condition a single-zone application such as the lobby of the office building, while the RTUs cool and ventilate the multi-zone office parts of the building with the help of the ERV.

DOAS units and RTUs can also provide different functions within the same zone, with the DOAS focusing on dehumidification while the RTU handles heating or cooling. The DOAS unit can be configured to deliver air into the return plenum of the RTU or directly to the space.

Learn More

Your local Greenheck representative can talk through the solution that works best for your application, so don’t hesitate to reach out. These links also have information about RTUs, energy recovery, and DOAS:

Energy Recovery Technologies (Product Application Guide)

Dedicated Outdoor Air System (DOAS) Fundamentals and Selection ConsiderationsDOAS Energy Recovery Rooftop Units

from