Fan motor speed depends on two things: the number of poles in the motor and the frequency going into the motor. You can use a VFD (variable frequency drive) to digitally change the frequency and manipulate the speed of a motor. This is often done to match the fan RPM (FRPM) in the design. Generally, running the motor at a frequency over 60 Hz is overspeeding and running it under 60 Hz is underspeeding. But when and why would overspeeding or underspeeding a fan motor be beneficial?

Meeting a Designed Fan RPM

Here’s a common situation where either overspeeding or underspeeding would be necessary. This scenario uses information available in Greenheck’s fan selection software.

| Model Name | Relative Cost | Operating Power (HP) | Required Power (HP) | Total External SP (in. wg) | Operating Frequency (Hz) | Fan Speed (RPM) | Non-Adjusted Motor Speed (RPM) |

| USF-24-B1 | 1.11 | 6 | 6 | 2 | 47 | 1,390 | 1,770 |

| USF-24-B1 | 1.16 | 6 | 6 | 2 | 71 | 1,390 | 1,170 |

| Table 1 |

- In this example, a direct drive fan has a design point of 10,000 cfm at 2 in. of external static pressure and a resulting fan speed of 1,390 rpm.

- Nominal motor RPM for a 4-pole motor is 1,770 and nominal RPM for a 6-pole motor is 1,170, so to achieve a 1,390 FRPM a VFD must be applied to either motor.

- Which is the better solution? Overspeed the 1,170 rpm motor, or underspeed the 1,770 rpm motor?

Overspeeding vs. Underspeeding

To understand the main reason why overspeeding works better than underspeeding, let’s go through the following example.

|

| Figure 1 |

|

| Figure 2 |

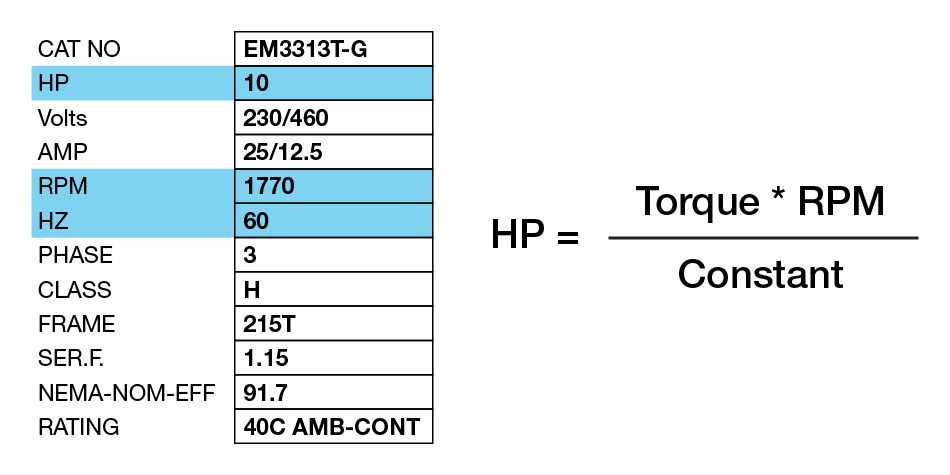

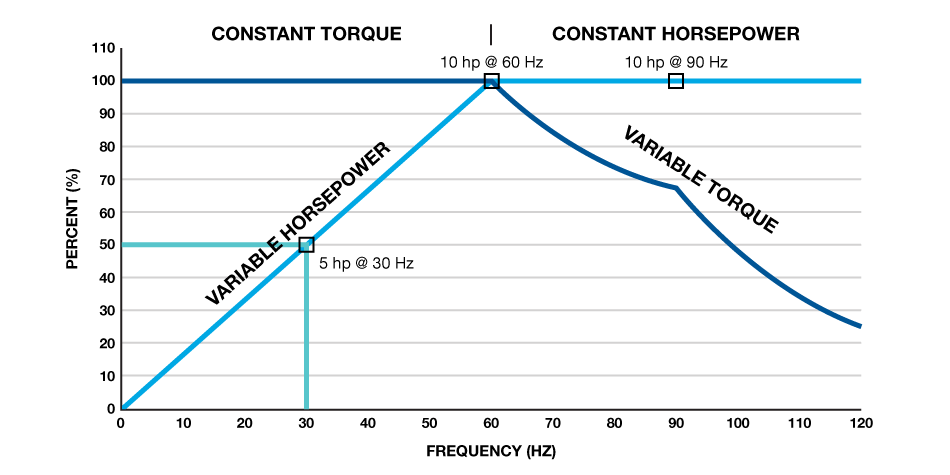

This example uses a 10 hp, 1,770 rpm motor. If the motor is operated at 60 Hz it will produce the 10 hp or full nameplate horsepower shown in Figure 1. If the motor is slowed down to 30 Hz using a VFD, as Figure 2 illustrates, the result is a reduction in available HP.

Using the formula “HP = Torque * RPM divided by a Constant” in Figure 1, you will notice in Figure 2 that torque remains constant but RPM falls off as the motor travels down the variable horsepower curve, resulting in 5 hp available at 30 Hz.

Conversely, if the motor is run above 60 Hz with a VFD, it will be traveling along the constant HP curve. Referencing the formula again, you will see that variable torque falls off at the same rate that RPM is increased, so they offset one another, resulting in the motor producing full nameplate horsepower throughout the overspeed condition.

If you were to underspeed the 1,770 rpm motor option mentioned earlier, it would need to be slowed down to 47 Hz to achieve the design point of 1,390 rpm at 6 Bhp (brake horsepower). A 7.5 hp motor at 47 Hz has 5.875 hp available when applying the linear derate from this example, so the motor HP has to be increased to 10 to have enough HP available at the turndown speed. 10 hp at 47 Hz has 7.833 hp available.

The better option is to overspeed the 6-pole 1,170 rpm motor using a VFD to achieve an FRPM of 1,390. Again, the design point requires 6 Bhp, and because the motor maintains full nameplate horsepower of 7.5 at overspeed, it can achieve the duty point without oversizing the motor. The overspeed selection is a more cost-effective option because it allows for a smaller HP motor.

Another benefit of overspeeding can be seen when a VFD is used in bypass. A fan operating over 60 Hz for a normal duty point would slow down if run in bypass, whereas the opposite is true if an undersped selection is run in bypass. In that case, it would try to speed up, possibly trying to consume more horsepower than what is available and/or subjecting the ductwork to pressures it is not designed for.

Underspeeding to an output frequency below 60 Hz also causes the output voltage to vary directly with the frequency. For example, a 460V drive will provide 460V output at 60 Hz but will only provide 230V at 30 Hz.

Safety of Overspeeding Motors

There is a longstanding perception in the industry that VFDs are designed to slow motors down below 60 Hz and that overspeeding a motor will shorten the motor life.

When a motor fails from overspeeding, there are typically two reasons:

- Insulation on motor windings: If overheated, the life of the insulation could be degraded, resulting in an eventual electrical short within the motor.

- Bearings: If these are not sized properly and then sped too fast, they can wear out more quickly.

To avoid these issues, make sure a motor is suitable for overspeeding, and do not exceed the motor nameplate amperage at any point across the operating range. Motor manufacturers commonly design for the performance requirements of overspeeding. 4-pole motors up to 30 hp can operate on a VFD up to 90 Hz without concern of winding insulation breaking down or premature bearing wear.

Conclusion

When multiple fan selections are available for a specific design point, many factors such as connected load, total HP, BHP, efficiency, sound, first cost, and others should be considered for the best solution. Overspeeding versus underspeeding the motors should also be a consideration in your design. When possible, select a system that is as close to nominal motor speed as available. If a decision has to be made to overspeed or underspeed—choose overspeeding!

Your local Greenheck representative would always be glad to answer questions about Greenheck products, overspeeding and underspeeding fan motors, or how to select the best motor for your application.

from