Make-up air units make up the air that is exhausted through an HVAC system. They are used in a variety of applications including commercial kitchens, manufacturing, and warehouses. Make-up air units can heat incoming air using a direct gas flame, indirect gas flame, or electric heat, as well as being able to cool it using packaged direct expansion (DX). The many variables that must be controlled for a make-up air unit include temperature, occupancy, lockout points based on the outdoor air temperature, coordination with dampers, and alarm conditions.

Staff in a kitchen or factory could be responsible for manually controlling everything themselves, or they can let the manufacturer preprogram controls sequences using a microprocessor. The difference between using a make-up air unit without a microprocessor controller and with one is like the difference between driving a twentieth-century car without digital features and driving a car today with smart features that improve safety and performance.

Microprocessor Controllers Simplify Operation

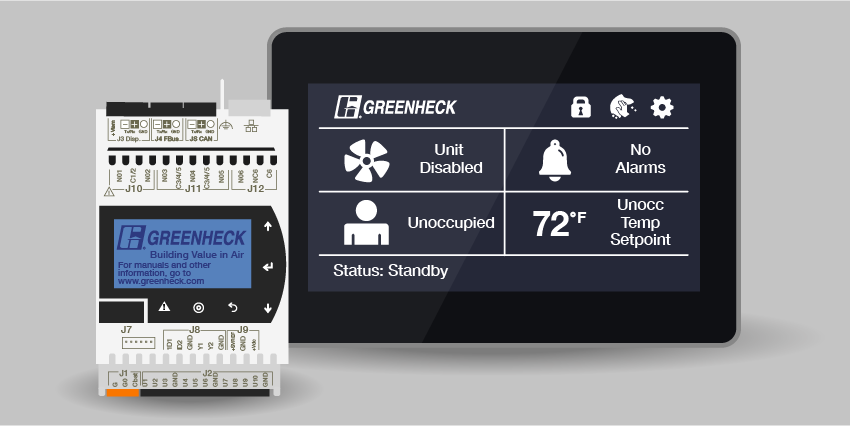

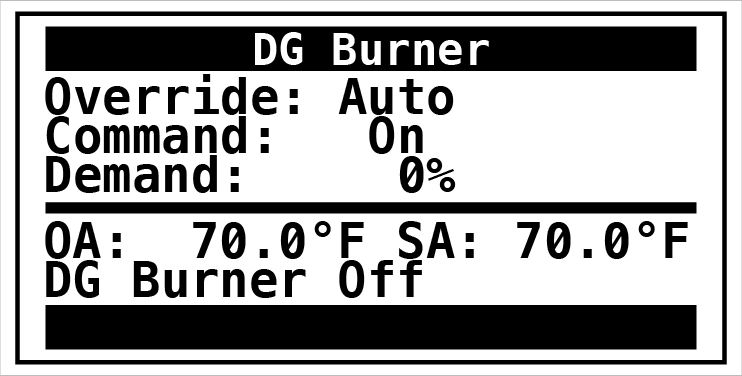

Microprocessor controllers simplify daily make-up air operations by providing standard optimized controls settings for every unit that are also flexible to changes in the field. Controls are factory-programmed, can be configured to the desired settings during test and balance, and can always be modified. They provide a lighted touchscreen with a web user interface (UI) that can be remotely monitored, allowing for troubleshooting and servicing away from the unit. The detailed fault codes and messages onscreen make troubleshooting simpler by reducing guesswork.

|

| Service Override Screen in Microprocessor Controls |

Microprocessor controllers include built-in commissioning menus for both direct and indirect gas-fired models. They adjust output based on changing conditions such as outdoor air temperature, removing the need for frequent manual adjustments.

Controllers Maximize Comfort

By monitoring inputs such as the previously mentioned outdoor air temperature as well as space air temperature, and adjusting the make-up air output in real time, the controller keeps spaces more comfortable. It also ensures that the unit is making up enough air to replace the exhaust air, preventing uncomfortable negative air pressure. Also, by monitoring setpoints for units using packaged DX cooling, the controller can help cool areas such as hot commercial kitchens when needed. Direct control of space conditions using a microprocessor helps spaces stay within operating limits for optimal temperatures.

Conserve Energy with Factory-Programmed Controls

Microprocessor controllers adjust make-up air depending on occupancy to avoid unnecessary energy usage and save operating costs. They allow the user to set occupancy schedules for each day of the week. The controller can also determine occupancy by accessing the building management system (BMS) or through user input, as well as allowing for “always occupied” and “always unoccupied” settings. It varies the speed of the supply fan based on changing needs from the space. For instance, during non-peak cooking times in a kitchen, the controls sequence can reduce the fan speed by 50% to save energy.

Microprocessor controllers can also detect faults in the system that cause inefficiency, such as a fan failure, which helps keep maintenance up to date. And by coordinating with the BMS, the make-up air unit can avoid conflicts with other equipment that could be inefficient, such as simultaneous heating and cooling.

Improve Safety by Coordinating with Building Systems

Integrating make-up air controls with the building management system contributes to safety, particularly when it comes to fire detection. In tandem with the fire alarm system, the controller can automatically shut down make-up air and fan operation to stop the spread of smoke and flames. The controller also monitors gas and flame conditions related to heating and detects if there is a leak in the refrigerant used for cooling.

Due to the many variables the system monitors, many different alarms and status messages can appear on the display. The system can log up to 100 different alarms, which helps with troubleshooting. Remote access to the system allows operators and technicians to catch and address safety issues in real time.

Microprocessor controls are not just used in make-up air, but in other HVAC/R equipment such as Dedicated Outdoor Air Systems (DOAS) and rooftop units (RTUs). Get in touch with your nearest Greenheck representative to ask any questions you have about incorporating microprocessor controllers in your next project.

Make-up Air

from