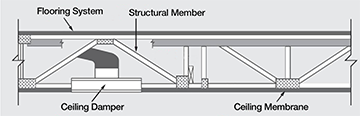

Ceiling dampers, also called ceiling radiation dampers (Figure 1), are crucial components of fire-rated floor/ceiling and roof/ceiling assemblies. However, confusion often occurs during the specifying and selection of these products. It is common to install the wrong damper, or worse, install each into assemblies that do not permit dampers. This could result in potential delays and added cost since a single project may have hundreds of dampers.

.png?sfvrsn=bd560cc4_2) |

| Figure 1 - Ceiling Damper Products |

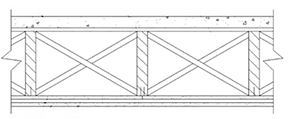

The UL Fire Resistance Directory contains design specifications for hundreds of different fire-rated building elements. It includes fire-rated walls, floor/ceiling assemblies, roof/ceiling assemblies, beams, and columns. Each meets the ANSI/UL 263 – Fire Resistance Ratings requirements. Many fire-rated floor/ceiling and roof/ceiling assemblies listed require a ceiling membrane to protect the structural members of the assembly during a fire (see Figure 2). Fire-rated acoustical ceiling tiles or gypsum boards are the most common materials used as a ceiling membrane in these designs.

|

| Figure 2 – Floor/Ceiling Assembly |

The ceiling membrane plays a critical role in maintaining the integrity of these assemblies during a fire. Any penetrations (openings) in the membrane require protection and are evaluated during the fire test. Ceiling dampers serve as that protection for penetrations made by HVAC equipment.

Different assemblies have different ceiling damper requirements

Is the ceiling damper you are considering approved for use in a specific fire-rated floor/ceiling or roof/ceiling assembly? Possibly. However, you can know for sure, if you understand how the UL Fire Resistance Directory lists these assembly designs relative to ceiling dampers. The following points can lead to confusion if you are not careful.

- Fire-rated floor/ceiling and roof/ceiling assemblies that require ceiling membrane protection are tested to the UL 263 standard. These fall into one of three categories as each pertains to ceiling dampers:

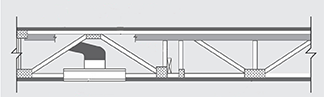

--Assemblies tested without ceiling dampers. (Figure 3) These assemblies do not allow installation of ceiling dampers.

|

| Figure 3 – Common Example of a fire rated floor/ceiling assembly without a ceiling damper |

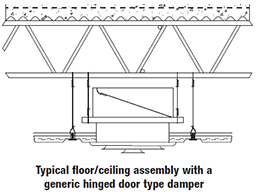

--Assemblies tested with hinged-door-style dampers. (Figure 4) Any damper that is UL 555C approved regardless of manufacturer, is acceptable for installation into this type of assembly. UL 555C is the test standard used to certify specific ceiling damper models by comparing performance with a generic hinged door damper.

|

| Figure 4 – Example of a fire rated floor/ceiling assembly with generic hinged-door damper |

--Assemblies tested with a damper model made by a specific manufacturer. (Figure 5) This limits damper models and manufacturers. All combustible (i.e. those with structural members made from wood) floor/ceiling and roof/ceiling designs that permit ceiling dampers require the use of manufacturer specific damper models. Dampers that only carry a UL 555C approval may not be used in combustible assemblies unless they are specifically listed in the applicable design.

|

| Figure 5 – Example of a combustible fire rated floor/ceiling assembly with manufacturer specific damper |

Did you intend to limit your options?

Here is an important point to consider. A manufacturer often pays for testing floor/ceiling and roof/ceiling assemblies that require a specific damper manufacturer and its product(s). Doing this means dampers approved for that design must be manufactured or licensed by that manufacturer, and listed in the design. This isn't a problem if the person specifying the floor/ceiling or roof/ceiling design has a strong preference for that particular damper brand. A single design listing may be specified, and construction is limited to only those materials and components listed in that design in that case. Unfortunately, this often is not what the specifier wants.

Many times, a person may specify a single design listing without realizing how this limits bids to one manufacturer. It is more likely the specifier simply wants to specify an assembly meeting the code-mandated fire-resistance rating and the general construction requirements (for example, a wood truss assembly with a specific truss depth). To accomplish this and allow bids from multiple brands, specifiers should do one of the following:

- Specify multiple floor/ceiling design numbers

- Specify designs that are open, meaning the design is not controlled by a single manufacturer

Understanding the proprietary nature of the UL Fire Resistance Directory along with the associated test standards and approvals will help keep your options open and avoid costly errors. The result will be a completed project with the correct ceiling dampers selected and installed the first time and at the right price, making the customer very happy.

Learn more about ceiling dampers in this in-depth article on ceiling dampers and then, find the correct ceiling damper for your application.

Dampers

from