What You Need to Know About Fire Ratings to Select the Correct Ceiling Radiation Damper

Selecting the correct ceiling radiation damper (firestop flap for our friends in Canada) requires a solid understanding of the testing and expected damper performance. This understanding guides the selection based on the protection needed and shows the importance of proper selection and installation of the damper assembly. However, the ratings associated with ceiling dampers can be confusing since it is possible to have ceiling radiation dampers approved for several applications depending on the installation.

Ratings: Fire-Resistance versus Fire-Protection

What is the difference between a fire-protection rating and a fire-resistance rating? Many products that protect openings have a fire-protection rating. However, assemblies designed for walls, floors, and ceilings must have fire-resistance ratings, per the International Building Code (IBC), specifically in ASTM E 119: Standard Test Methods for Fire Tests of Building Construction Materials or ANSI/UL 263: Fire Tests of Building Construction and Materials. The tests look at heat transfer through the membrane elements protecting the frame and surface of structures to confirm the assembly meets the stated criteria. The testing ensures proper performance in minimizing or preventing the fire from spreading and reducing the likelihood of structural failure.

Stated another way, the purpose of wall or ceiling assemblies having a fire-resistance rating is to:

- Support an applied structural load

- Prevent the spread of hot gases or flames through the exposed wall/ceiling

- Limit temperature rise on the unexposed side so combustible materials on the unexposed side do not ignite from increased radiant heat

Products having a fire-protection rating (in general) only limit flames and do not prevent an increase in temperature from passing through to the unexposed side. Based on this information, ceiling dampers in floor/ceiling or roof/ceiling assemblies must have a fire-resistance rating instead of a fire-protection rating.

Selecting Ceiling Dampers

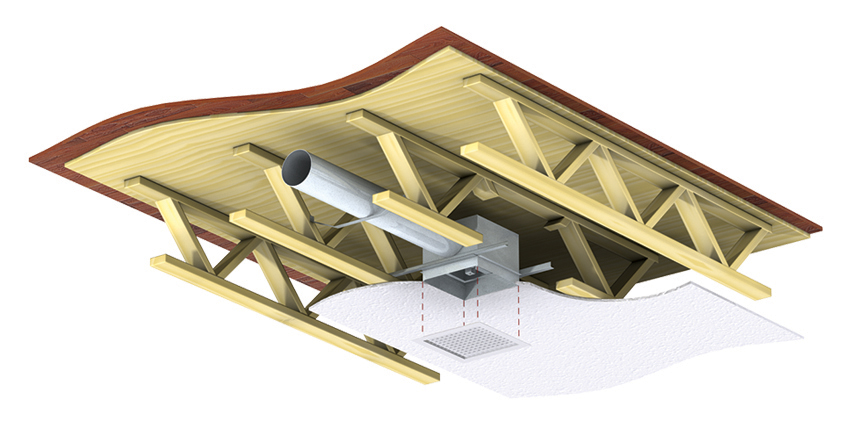

Selection for ceiling dampers involves much more than finding one with the desired features. The process requires a thorough understanding of the floor/ceiling or roof/ceiling assembly design because ceilings, like the assemblies installed, have different fire ratings. For example, a UL 555C-rated ceiling damper can provide the desired protection for air inlet/outlet penetrations while having a three-hour fire-resistance rating (assuming proper installation in the correct application). The ceiling damper in this example eliminates using a hinged-plate damper or similar protection methods for the design shown in the UL Fire Resistance Directory.

Buildings of wood construction can also pose a challenge when selecting ceiling radiation dampers. Approvals for ceiling dampers in wood construction differ from those required for other structures. Knowledge and understanding of ANSI/UL 263 are a must. This standard defines the test criteria to evaluate all building elements, including floor/ceiling assemblies, for fire resistance.

Referencing the UL Fire Resistance Directory for Wood Construction

Summarizing Fire Ratings and Ceiling Dampers

A fire protection or fire-resistance rating is assigned to assemblies protecting openings in a tested fire-rated assembly. The IBC provides a detailed explanation of these ratings as it applies to building elements, components, and assemblies using test procedures explained in ASTM E 119 and ANSI/UL 263. However, a fire protection rating for a ceiling damper with UL 555C or a fire damper with UL 555 certification does not automatically allow use on a floor or ceiling assembly. You can and should refer to the UL Fire Resistance Directory, but a better approach is contacting your local Greenheck representative.

from