Building codes require life safety dampers to protect openings in walls, ceilings, floors, and/or partitions to prevent the spread of fire and/or smoke. The four types of life safety dampers are:

- Fire dampers

- Smoke dampers

- Combination fire smoke dampers

- Ceiling radiation dampers

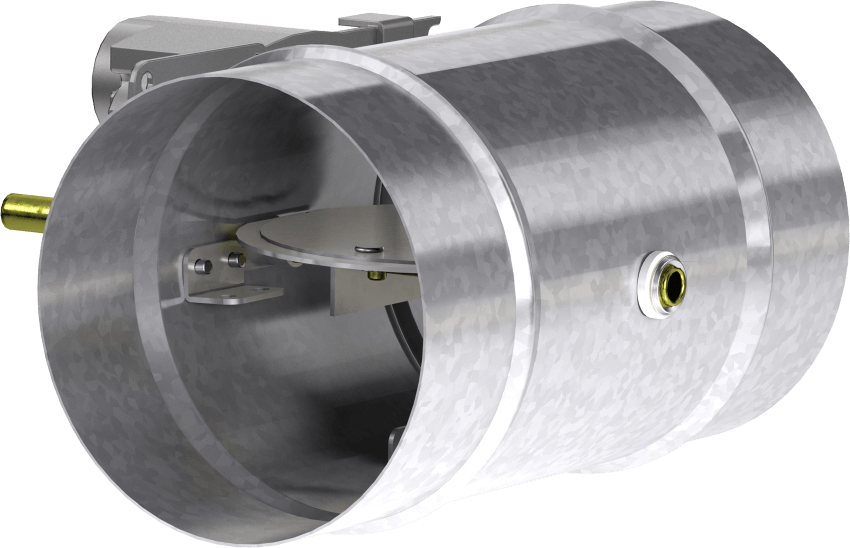

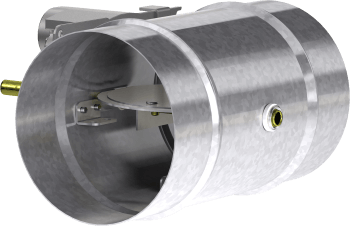

Round ductwork requires true round fire, smoke, and combination fire smoke dampers or square dampers with round transitions. True round life safety dampers (Image 1) save time and money over traditional square dampers with round transitions (Image 2).

|

| Image 1: True Round Life Safety Damper |

|

| Image 2: Square Life Safety Damper with Round Transition |

Construction

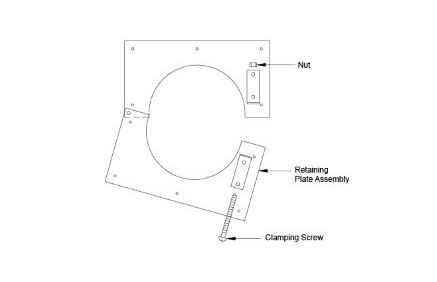

True round life safety dampers are typically constructed from galvanized steel but can also be ordered with 304 or 316 stainless steel. Depending on the type of damper, they can be supplied with a variety of accessories. All round life safety dampers feature an integral sleeve for easy connection to adjoining ductwork. Many manufacturers of true round fire, smoke, and combination fire smoke dampers have a factory-supplied retaining plate for easy mounting into a standard square-framed opening (Figure 1). The square one-piece retaining plate wraps around the sleeve of the damper and tightens with the clamping screw. They are designed to mount flush to the wall/floor and hold the damper in the square opening. Click Here to watch a short installation video. The use of factory-supplied retaining plates on true round dampers eliminates the need for traditional retaining angles required for square/rectangular fire and fire/smoke dampers.

|

| Figure 1: Retaining Plate - Included with all true round dampers. |

Ratings

Dynamic-rated true round fire dampers are appropriate for use in dynamic (or static) systems with airflow velocities up to 2,000 fpm (10.2 m/s); true round smoke and combination fire smoke dampers are appropriate for use in systems with airflow velocities up to 4,000 fpm (20.3 m/s). They are rated for pressures up to 4 in. wg (1 kPa), temperature up to 350°F (177°C), and up to 3-hour fire rated. True round fire, combination fire smoke, and smoke dampers are ideal for use where you need to connect to round ductwork or where minimum pressure drop is desired and are available in diameters up to 24 inches (610 mm). These dampers are UL approved to be installed vertically to protect wall penetrations and horizontally to protect floor penetrations.

Codes and Standards

The terms “code” and “standard” are often used interchangeably, but there is a difference. Codes are specific written regulations and requirements using appropriate language with the expectation that they will become law. A standard establishes a defined level of performance but may not become a law. Codes often reference certain standards. Life safety dampers have many code/standard requirements, including IBC (International Building Code), and standards issued by several various agencies: UL (Underwriter’s Laboratories), NFPA (National Fire Protection Association), CSFM (California State Fire Marshall), and AMCA (Air Movement and Control Association International). The dampers should be labeled indicating they have met the criteria.

Installation

Installations of life safety dampers in round ductwork have historically required a square damper with round transitions on either end. Manufacturers have changed this over the past 5 to 10 years, developing true round-style fire, smoke, and combination fire smoke damper models.

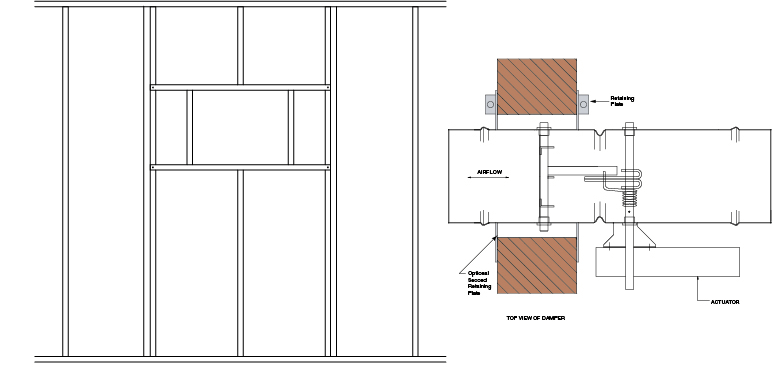

While round ductwork is a common feature in many buildings, these true round life safety dampers are underutilized due to a lack of awareness and misconceptions about the true round products. One of the most common misconceptions is that round dampers require a round hole in the wall. This is simply not true. In fact, framing for the opening of a round life safety damper is exactly the same as a square damper (Figure 2).

|

| Figure 2: The opening in the wall does not have to be round. |

Advantages

True round life safety dampers have several competitive advantages when compared to similar square damper models with round transitions:

- Lower cost – round life safety dampers are more cost-effective and can be as much as 45% less expensive.

- Easier to install – round dampers are lighter and easier to maneuver. Round dampers can be easily installed in a square opening with a factory-supplied retaining plate.

- Easier to size – ordering the correct size is simplified because you only need to know the duct diameter.

- Lower noise – even airflow distribution creates less noise in the system.

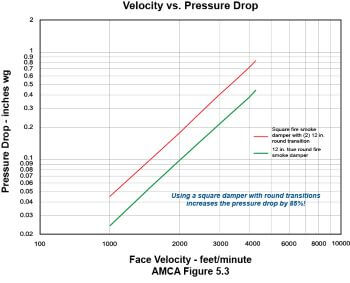

- Better pressure drop performance – round dampers provide a seamless transition to ductwork with minimal obstruction in the airstream (Figure 3). Performance can be improved by as much as 85%, depending on size and manufacturer.

|

| Figure 3: Pressure Drop of true round model FSDR-510 vs. FSD-211 w/round transition. |

With round ductwork being more efficient by creating less airflow resistance, they are being installed more in buildings. Specifying true round life safety dampers will save the project time and money over the traditional square damper with the round transition. These true round life safety dampers can easily be installed in square wall openings and provide many other benefits.

Dampers

from