Understanding the Differences Between Backdraft and Relief Dampers – Application and Selection

|

| Figure 1 |

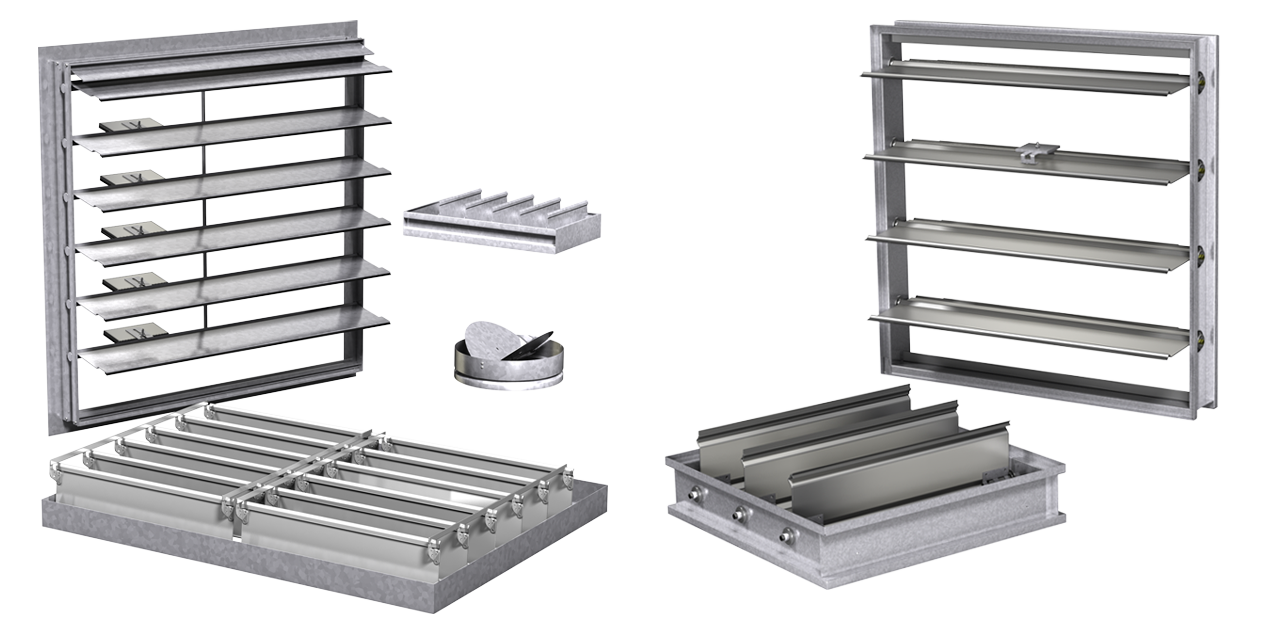

Backdraft dampers, also known as gravity dampers, are used in ventilation systems to allow airflow in one direction and prevent airflow in the opposite direction. A relief damper has an elevated and adjustable start-open pressure while providing the backdraft function - think of it as controlled leakage in the direction of flow. The following discusses specific types of backdraft and relief dampers, including the operation and uses of each.

Commercial Backdraft Dampers

A commercial backdraft damper (Figure 2) is a gravity damper when non-motorized allowing airflow in one direction only. For example, when placed on a propeller fan, it will prevent the wind from causing the fan to run backward when the power is off. When a backdraft damper is motorized, it functions as a control damper.

|

| Figure 2 |

Backdraft dampers may utilize springs, adjustable counterbalance weights, or a motor pack to assist with opening the damper blades.

- Spring-assist means the spring is attached to the damper that helps open or close the damper blades. The spring is adjustable using a series of holes in the frame or blade assembly to increase or decrease the tension.

- Adjustable counterbalance weights are a more precise means of reducing the pressure required to open the damper.

- A motor pack is necessary when the damper needs to open and close without relying on air velocity or pressure.

Applications for commercial backdraft dampers are:

- Exhaust

- Air intake

- Roof ventilation

- Sidewall ventilation

- In-duct ventilation

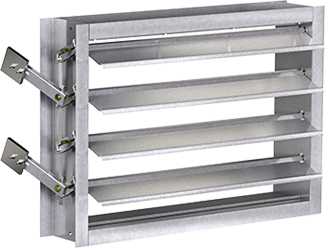

Heavy Duty/Industrial Backdraft Dampers

|

| Figure 3 |

Applications for heavy-duty/industrial backdraft dampers are:

- Blower outlets

- Branch duct isolation

- Industrial process isolation

- Emergency generator radiator outlets

Relief Dampers

Relief dampers are backdraft dampers with an adjustable start-open pressure capable of maintaining a relatively constant pressure at various airflows, then closing upon a decrease in differential pressure. Uses can include pressure build-up in zoned duct systems that could potentially cause damage to HVAC equipment.

Barometric Relief Dampers

|

| Figure 4 |

Applications for barometric relief dampers are:

- Gravity hood intake and exhaust

- Stairwell pressurization

- Room pressurization

- Ductwork outlets

Heavy-Duty/Industrial Pressure Relief Dampers

|

| Figure 5 |

A pressure relief damper may be a safety device or a controlling device. It can mount in a duct section to relieve an unexpected overpressure or relieve duct vacuum downstream of a rapidly closing fire damper. These dampers can also be used as a control device, such as opening to allow additional air when used parallel to a direct fire gas burner or allow more air into fume exhaust to maintain 3000 feet per minute (fpm) exhaust velocity.

Applications for heavy-duty/industrial pressure relief dampers are:

- Fume exhaust

- Duct/plenum protection

Energy Code

The two common energy code standards (Figure 6) that pertain to backdraft dampers are:

- ASHRAE Standard 90.1 – Energy standard for Building Except Low-Rise Residential Buildings

- IECC - International Energy Conservation Code

|

| Figure 6 |

Both IECC and ASHRAE codes state that gravity (non-motorized) dampers shall have an air leakage rating not greater than 20 cfm/ft² where not less than 24 inches in either dimension and 40 cfm/ft² where less than 24 inches in either direction. The rate of air leakage shall be determined at 1-inch water gauge when tested in accordance with AMCA 500-D for such purpose. IECC additionally requires backdraft dampers to be labeled by an approved agency, such as the Air Movement and Control Association, International.

Selection of a Backdraft Damper

When selecting the correct damper for your application, you will need to know the following:

- Airflow direction

- Damper operation (gravity or motorized)

- System velocity and back pressure requirements

- Mounting configuration (inserted into the duct/opening or flange mounted)

- Mounting orientation (vertical, horizontal airflow up, horizontal airflow down)

- Start-open pressure

- System velocity and back pressure requirements

This information will help determine whether a backdraft or relief damper works best for the application.

Learn more about backdraft and heavy-duty industrial dampers.

References: 2021 IECC (International Energy Conservation Code)

2019 ASHRAE 90.1 Energy Standard for Buildings Except Low-Rise Residential Buildings

Dampers

from