Kitchen Direct Gas-Fired Make-up Air Units

Direct gas-fired make-up air units feature burners that are 92% efficient and capable of up to 30:1 turndown for more precise temperature control. The burner construction consists of a cast aluminum manifold with stainless steel mixing and end plates, drastically reducing burner maintenance in the field. These units can be configured with a wide variety of heating/cooling capacities and air volumes to fit any commercial kitchen application.

OVERVIEW

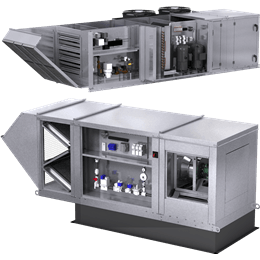

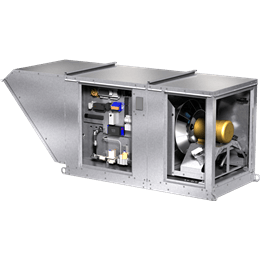

DGX

Model DGX is a highly configurable direct gas-fired heating and cooling system. The unit incorporates a modular design to maximize configuration flexibility. In addition, constant volume, 100% outdoor air, recirculation, and VAV airflow arrangement are available. The DGX can be configured with a forward-curved, backward-curved or mixed flow plenum supply fan allowing for either belt-driven or drive arrangements.

- 800 to 48,000 cfm and 4 in. wg

- Up to 4,800,000 BTU/hr.

- Cooling options: packaged direct expansion (DX), chilled water, or evaporative cooling

- ETL listed