Make-up Air Controls

Investigate a full suite of control solutions specifically designed to operate efficiently and effectively. These controllers can operate stand-alone or integrate with building management systems (BMS). The right solution for your application is here.

OVERVIEW

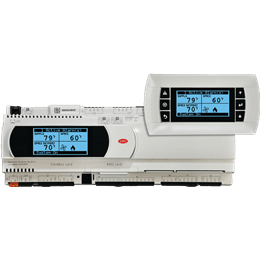

Remote Touchscreen Interface

The remote touchscreen interface for Make-Up Air unit control offers advanced capabilities for control of Make-Up Air units with the simplicity of an intuitive LCD display. This cutting-edge accessory allows the end user to control any Make-Up Air unit with heating and cooling from the space, allowing maximum flexibility and convenience. The remote touchscreen interface supports fan enable and disable, unit set points, password protection, the ability to communicate with a building management system (BMS) through BACnet MS/TP, and much more!

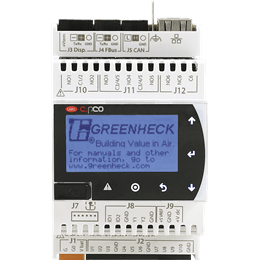

Microprocessor

Furnace Control

Indirect gas-fired furnace units come with a standalone furnace controller. The furnace control has a keypad and easy-to-read LCD display allowing users to adjust all set points, lockouts and delays. It includes a furnace-commissioning menu with preprogrammed steps through the furnace start-up. The controller monitors furnace operations for alarm conditions. The unit will record the alarm description, time, date, available temperatures and furnace status for the user. The furnace control also reserves a digital output for remote alarm indication.

Remote Panels

The optional remote panel makes field wiring between the remote panel and unit easier. Labels are the same for terminals on the remote panel and unit (example: R to R, G to G, etc.). What's more, switches on the remote panel replace the need for someone in the field to provide contacts for fan enable, heat enable and cooling enable. Indicator lights for operation, warnings and alarms are available options on the remote panels. Remote panels fit in NEMA rated enclosures (1, 2, 3, 3R, 4, 4X and 12) for many applications.

- Catalogs

-

Instruction Manuals

- IOM #476811 - Network Interface BMS v1.10

- IOM #483843 - Furnace Controller IGF v1.03

- IOM #485941 - BACnet Guide

- IOM #487036 - Microprocessor Controller MUA 4.1

- IOM #483235 - Microprocessor Controller MUA TAP v2.60

- IOM #485877 - Microprocessor Controller MUA v3.2

- Quick Start Guide #485931 - Microprocessor

- Other Product Information

- Warranty