High Plume Dilution Laboratory Exhaust Fans

The high plume nozzle and dilution windband entrain outside ambient air to assist in the increased dilution of laboratory exhaust while maintaining effective plume height. Higher nozzle velocity creates a higher dilution, diluting and dispersing potentially hazardous exhaust or fumes quickly and safely.

OVERVIEW

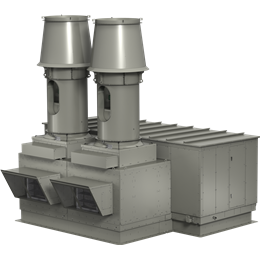

Vektor-CD

Vektor-CD utilizes a centrifugal blower with a backward-inclined flat or airfoil bladed wheel, making it ideal for systems requiring horizontal exhaust duct runs or having higher system pressures. There are three configuration options for belt or direct drive models. These are single, multiple parallel or opposed fan systems using up to four fans with a common plenum.

- 1,500 to 122,000 cfm per fan

- Up to 13.5 in. wg

- Spark C or B resistant construction

UL/cUL Listed for Electrical (UL/cUL 705)

AMCA licensed for FEI, Air, Sound and Induced Flow Performance

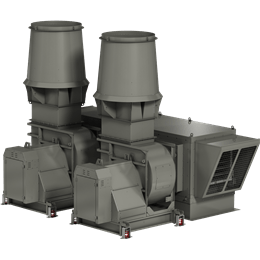

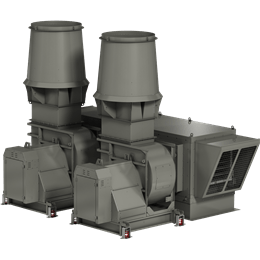

Vektor-MD

Vektor-MD utilizes an inline mixed flow fan available in belt or direct drive configuration both with a bifurcated housing, keeping drive components out of the contaminated airstream. The windband and nozzle combination entrain ambient air to assist in the dilution of the contaminated exhaust. Available with up to six fans on a common plenum, the Vektor-MD fan(s) can also be supplied with the Vektor-ERS, energy recovery system.

- 1,500 to 83,000 cfm per fan

- Up to 11.5 in. wg

- Spark C or B resistant construction

UL/cUL Listed for Electrical (UL/cUL 705)

AMCA licensed for FEI, Air, Sound and Induced Flow Performance

- Options and Accessories

- Catalogs

-

Instruction Manuals

- Vektor-CH, CD and CS (#471555 IOM)

- Vektor-MH, MD and MS (#464652 IOM)

- Vektor-M Series Roof Curb (#475588 IOM)

- Vektor-C Series Fastener Kit – Windband to Nozzle (#1016014 IOM)

- Vektor-M Series Fastener Kit – Fan to Bypass Air Plenum (#1016005 IOM)

- Vektor-M Series Fastener Kit – Nozzle to Stack and Stack to Fan (#1016006 IOM)

- Vektor-M Series Fastener Kit – Dilution Nozzle to Fan (#1016008 IOM)

- Vektor-M Series Fastener Kit – Inline Silencer (#1016009 IOM)

- Vektor-M Series Fastener Kit – Fan Assembly to Roof Curb (#1016010 IOM)

- Energy Recovery Systems (ERS) (#474118 IOM)

- Vektor-M Series Fastener Kit – Bypass Air Plenum to Energy Recovery Plenum (#1016722 IOM)

- Vektor-ERS Curb Assembly (#474117 IOM)

- Vektor-ERS Fastener Kit – Knock Down ERS Roof Curb (#1016916 IOM)

- Vektor-ERS Fastener Kit – ERS Curb Insulation Clips (#1016917 IOM)

- Vektor-ERS Fastener Kit – Plenum Assembly to Roof Curb (#1016918 IOM)

- Vektor-ERS Fastener Kit – Interior Section of Modular Roof Curb (#1032090 IOM)

- Jib Crane (#472081 IOM)

- Vektor System Controls (#483903 IOM)

- Vektor System Controls v1.20 (#486121 IOM)

- Sure-Aire Electronics (#1021624 IOM)

- Specifications

-

Drawings

-

STATIC MODEL DOWNLOAD3D CAD2D CAD

-

Vektor®-CD

Vektor®-CD Vektor®-MD

Vektor®-MD

-

-

Application Information

- Vektor System Control Comprehensive Guide

- An Analysis of Induced Flow Laboratory Exhaust Fan Systems and the Benefit of AMCA 260 Certified Performance FA/128-12

- Coatings Application Guide

- Fan Energy Index (FEI) (FA/135-25)

- Measuring Belt Tension (FA/127-11)

- Mechanical Room

- New Test Standard for Dilution Blowers (CS/102-11)

- Variable Volume Laboratory Systems, an Overview (FA/124-05)

- Videos

- Other Product Information

- Warranty

- Project Profiles