Fume Exhaust Fans

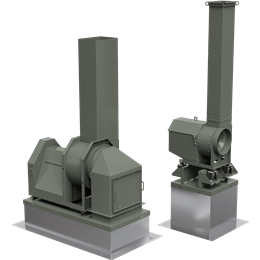

The FumeJet® exhaust fan is a pre-engineered, centrifugal exhaust system. Its design allows for safe exhaust and dispersion of contaminated air in commercial, institutional or industrial applications. FumeJet offers quick and easy package installation; slip-fit stack connections, inlet box, collar, and curb cap configuration. Direct, Isolated, roof curb and equipment support mounting types are avilable. The FumeJet exhaust fan simplifies an installation with options available to configure each unique application as an alternative to a field built-up system. This engineered system can be installed with or without Guy-wires further catering to the required application.

OVERVIEW

FJ

- Up to 18,000 cfm

- Up to 9 in. wg

- AMCA Spark B or C resistant construction (available)

Notice Of Acceptance (NOA High Wind)

UL/cUL Listed for Electrical (UL/cUL 705)

AMCA licensed for FEI, Air & Sound Performance

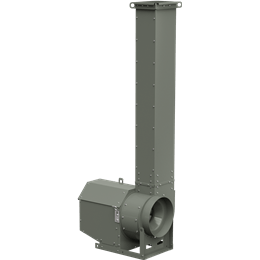

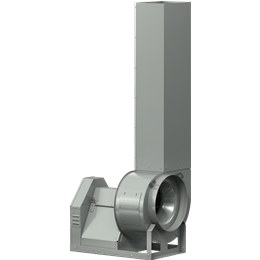

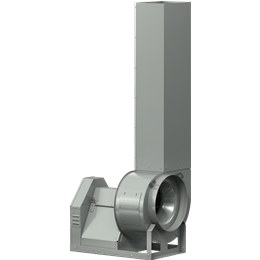

FJC-300

Model FJC is a belt-driven, arrangement 10 unit available in either coated steel or galvanized finish construction. The unit has a compact footprint with motor and drives located under a common weather hood. The fan and stack assembly has been designed and factory tested to withstand a force of 34 PSF (equivalent to 115 mph) without the need for guy-wires. Typical applications inlcude manufacturing exhaust, medical instrument sterilization, and isolation rooms.

- Up to 5,000 cfm

- Up to 4.5 in. wg

- AMCA Spark B or C resistant construction (available)

- 400°F max temperature (continuous)

Notice Of Acceptance (NOA High Wind)

UL/cUL Listed for Electrical (UL/cUL 705)

HCAI Seismic Certified

AMCA licensed FEI & Air (AMCA 210) sizes 6 - 10

AMCA licensed FEI, Air & Sound (AMCA 210 and 300) sizes 12 - 24

- Catalogs

- Instruction Manuals

- Specifications

-

Drawings

-

STATIC MODEL DOWNLOAD3D CAD2D CAD

-

FJC-300

FJC-300

-

- Application Information

- Videos

- Other Product Information

- Warranty