KITCHEN VENTILATION SYSTEMS

Manufacturing single-source complete commercial kitchen solutions since 1975.

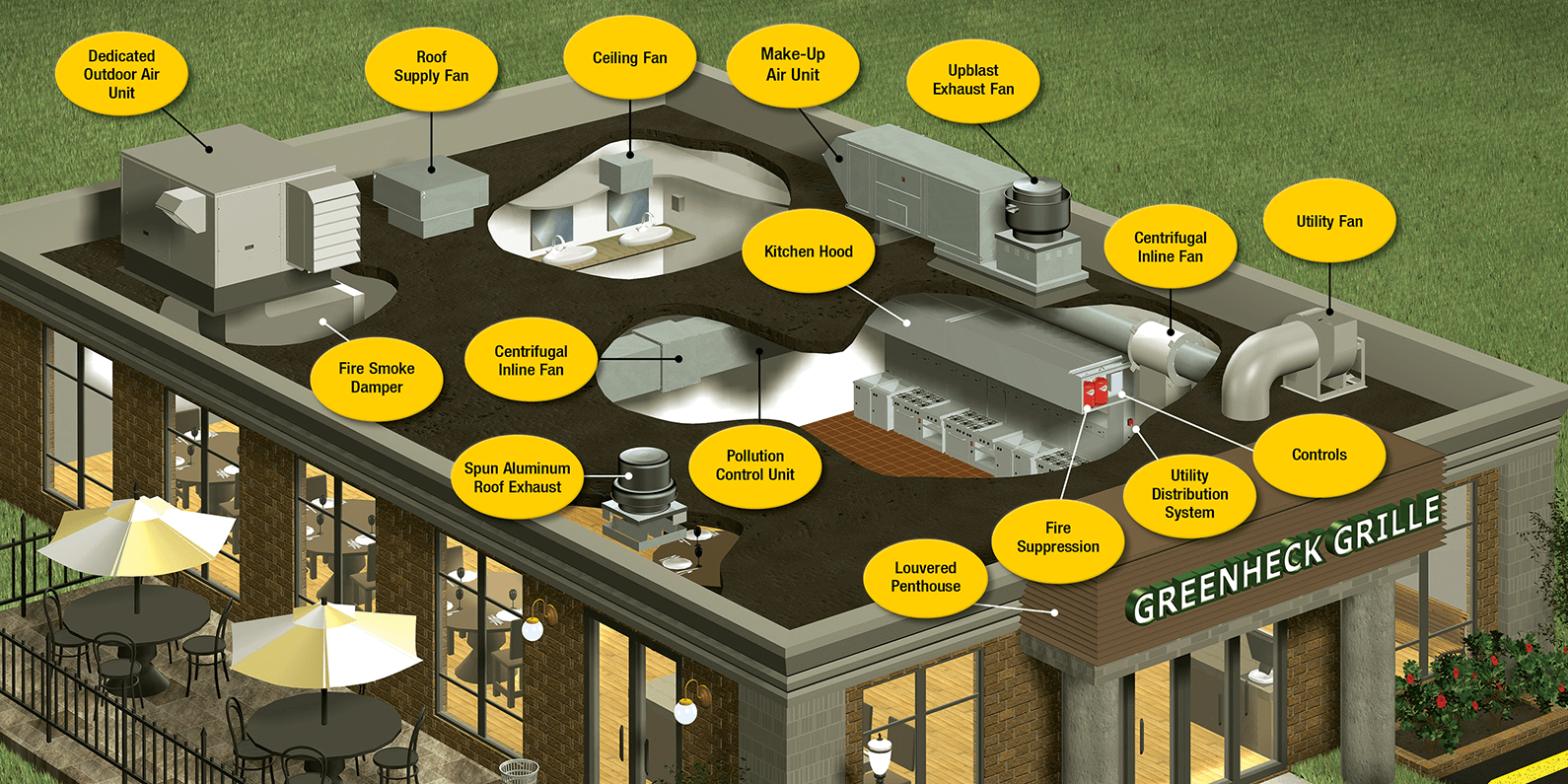

Since 1975 Greenheck has manufactured quality kitchen ventilation components and systems for restaurants and commercial kitchens. The breadth of our products and the experience of your local Greenheck representative offers you superior and reliable air movement, control and conditioning solutions you expect from an industry leader. Click on any of the product bubbles in the image of the Greenheck Grille or click the button below to view all kitchen ventilation products.