Variable Geometry Nozzle Laboratory Exhaust Fans

The Variable Geometry Nozzle (VGN) automatically adjusts to maintain the specified discharge velocity as airflow varies. This safely prevents re-entrainment in the make-up air unit. The VGN provides energy savings in reduced lab flow situations without introducing bypass air to maintain ANSI required outlet velocities.

OVERVIEW

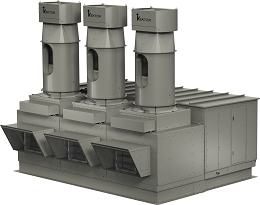

Vektor®-CS

The Vektor-CS safely maintains a constant discharge stack velocity at low volumes. This maintains ANSI guidelines for building design velocities regardless of laboratory exhaust airflow. The unit also reduces fan energy consumption on variable volume and demand-based ventilation systems. Drive components are out of the airstream. The motor is located at the roof deck level to the side of the common plenum. Vektor-CS is available in belt or direct drive and single to quadruple fan systems.

- 1,500 to 32,000 cfm per fan

- Up to 10 in. wg

- Spark C or B resistant construction

AMCA licensed for Air and Sound performance (AMCA 210 and 300)

UL/cUL Listed for Electrical (UL/cUL 705)

HCAI Seismic Certified

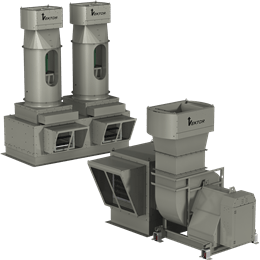

Vektor®-MS

The Vektor-MS is an inline fan with a bifurcated housing to keep drive components out of the contaminated airstream. Its variable geometry nozzle (VGN) technology recognizes changes in airflow and static pressure in an occupied space. This causes the fan’s operation to adjust throughout the day based on demand. Vektor-MS is available in belt or direct drive systems and up to four fans per system.

- 2,000 to 32,000 cfm per fan

- Up to 10 in. wg

- Spark C or B resistant construction

AMCA licensed for Air and Sound performance (AMCA 210 and 300)

UL/cUL Listed for Electrical (UL/cUL 705)

- Options and Accessories

- Catalogs

-

Instruction Manuals

- Vektor-CH, CD and CS (#471555 IOM)

- Vektor-MH, MD and MS (#464652 IOM)

- Vektor-M Series Roof Curb (#475588 IOM)

- Vektor-M Series Fastener Kit – Fan to Bypass Air Plenum (#1016005 IOM)

- Vektor-M Series Fastener Kit – Fan Assembly to Roof Curb (#1016010 IOM)

- Energy Recovery Systems (ERS) (#474118 IOM)

- Vektor-M Series Fastener Kit – Bypass Air Plenum to Energy Recovery Plenum (#1016722 IOM)

- Vektor-ERS Curb Assembly (#474117 IOM)

- Vektor-ERS Fastener Kit – Knock Down ERS Roof Curb (#1016916 IOM)

- Vektor-ERS Fastener Kit – ERS Curb Insulation Clips (#1016917 IOM)

- Vektor-ERS Fastener Kit – Plenum Assembly to Roof Curb (#1016918 IOM)

- Vektor-ERS Fastener Kit – Interior Section of Modular Roof Curb (#1032090 IOM)

- Variable Geometry Nozzle (VGN) Controls (#481885 IOM)

- Vektor System Controls (#483903 IOM)

- Vektor System Controls v1.20 (#486121 IOM)

- Sure-Aire Electronics (#1021624 IOM)

- Specifications

- Application Information

- Videos

- Other Product Information

- Warranty

- Project Profiles